-

Konjac glucomannan is acknowledged as one of the top ten health foods by the United Nations Health Organization[1], which is mainly extracted from Amorphophallus konjac, an underground tuber of the perennial herb of konjac in Araceae. Konjac has a good health care effect on reducing blood glucose, blood lipids, cholesterol, weight loss, regulating intestinal flora, and so on[2]. Therefore, it is being widely used in food processing.

Konjac gel food is a thermally irreversible gel formed by removing acetyl groups and can generate new chemical bonds when konjac glucomannan (KGM) is heated under alkaline conditions. The original helical structure of KGM disappears, and the number of hydrogen bonds increases, which also leads to poor water holding capacity of KGM[3]. Therefore, konjac gel food may be dehydrated during storage, resulting in a decline in product quality. Konjac cold noodles are a typical konjac food. The majority of konjac cold noodles on the market are made of pure konjac flour, and the alkaline is injected into the food package to extend the shelf life and stabilize the taste. However, it might cause some problems in the storage of konjac noddles. For example, alkali preservation leads to excessive alkali taste and poor taste of konjac flour and the volume of alkaline is too large, making transportation inconvenient.

When only using konjac flour as a raw material, konjac noodles would have undesirable properties such as unfavored taste and color, ease of breaking, and others, during storage[4]. By adding a fixed proportion of soybean protein isolate and sweet potato starch, the sensory quality can be largely improved, and the nutritional value can also be increased to some extent. The quality stability, especially for long-term storage, can be also promoted by creating a composite gel system. As a result, it can greatly reduce food loss and the cost of industrial production.

Wet food has high water activity, which is easy to cause corruption, mildew, and deterioration, so effective fresh-keeping measures are essential. Microorganisms have optimal growth pH environments. The optimal pH value of mold is 5~6, and the optimal pH value of bacteria is neutral[5]. Citric acid and calcium hydroxide can achieve the purpose of antisepsis and freshness preservation through their antibacterial properties and changing the pH of the food system that is not in favor of microbial growth[6]. The combination of pH control technology with other technologies can achieve the effect of extending the shelf life of food[7]. Vacuum packaging is a mature technology that has been widely applied for preserving food by isolating oxygen. As a result, the growth of aerobic microorganisms can be controlled[8].

Currently, there are no reports on the quality change of wet konjac noodles, especially the compound cold ones, during storage. Therefore, in this study, the noodles treated by acid soaking or alkali immersion, pasteurization, and vacuum packaging were prepared and the product quality was determined during the storage time at room temperature (28 ± 1 °C). The texture, pH, color difference, sensory quality, etc. were measured weekly, and the microorganisms were detected using the plate counting method. Our results would provide an experimental basis for wet konjac noodles to maintain stable shelf-life quality, which is promising for practical industrial production.

-

Konjac flour (KGM 74.85%, moisture 7.59%, crude protein 1.00%, ash 6.29%) was purchased from Zhenjiang Zhinong Food Co., Ltd. (Zhenjiang, China). Soy protein isolate was purchased from Shandong Dexinkang Biotechnology Co., Ltd. (Shandong, China). Sweet potato starch (moisture 12.38%, ash 0.12%, protein 0.23%, lipid 0.63%, amylose 24.3%) was purchased from Shandong Bio-Sunshine Co., Ltd. (Shandong, China). Ca(OH)2 was purchased from Nanjing Yijia-Xinwei Chemical Co., Ltd. (Nanjing, China). Citric acid was purchased from Jilin COFCO biochemical Energy Sales Co., Ltd. (Jinlin, China). The reagents and chemical materials used in this study were of analytical grade.

Preparation of KGM noodles

-

Before sample preparation, the workshop including industrial instruments were sterilized overnight using ultraviolet radiation and ozone generators. Firstly, 1.0 g of soy protein isolate and 2.5 g of sweet potato starch were added into 100 mL of deionized water and then were stirred by a mixer (JJ-1 Electric Mixer, Jintan Experimental Instrument Co., Ltd, Changzhou, China) for around 5 min at a speed of 300 rpm. After that, 3.0 g of KGM flour was slowly added at the same stirring speed. After swelling, stirring was continued while adding 30 mL of alkaline solution containing food additive Ca(OH)2. The mixed gel was then stood still at room temperature for 2 h. To form thermo-irreversible gel, the sample was heated in a water bath of 90 °C for 30 min. After cooling to room temperature, it was cut into strips of 1 cm × 8 cm and packed immediately (P290 intelligent vacuum packaging machine, Dongguan Yiguang Packaging Machinery Co., Ltd, Dongguan, China).

All the treatments for preserving the wet konjac noodles are displayed in Table 1, where the samples in CA group were only soaked in citric acid solution (pH = 3) for 10 min, and sealed in pre-sterilized autoclaved bags (PET/CPP, 1.8 mm; Heyi Printing Co., Ltd., Shanghai, China) with non-vacuum packing. The CF group was soaked in citric acid solution (pH = 3) for 10 min and pasteurized after vacuum packing. Different from CF group, CI group was changed into alkaline immersion (Ca(OH)2 solution, pH = 12). The condition for pasteurization was heated at 90 °C for 10 min and the degree of vacuum packaging was −0.07 ~ −0.08 MPa. The group CK was taken as the control group.

Table 1. Treatments for preserving wet konjac noodles.

Group Acid soaking Alkali immersion Pasteurization Vacuum packing CA + − − − CF + − + + CI − + + + CK − − − − Samples were pasteurized at 90 °C for 10 min and the condition for vacuum packaging was −0.07 ~ −0.08 MPa. '+' means to adopt and '−' means not to adopt. After treatment, samples were stored in an incubator (LCSH-150C, Nanjing Lianze Scientific Instrument Co., Ltd, Nanjing, China) at 28 ± 1 °C. The indexes of each group were measured at a storage time of 0, 1, 2, 4, 6, and 8 weeks.

Microbiological assay

-

Microbial growth of samples were regularly analyzed according to the standard for microbiological determination (GB 4789.2-2016) to determine the total bacterial count. The standards GB 4789.41-2016 and GB 4789.15-2016 were referred to determine of the number of Escherichia coli and the quantity of mold and yeast, respectively. Briefly, 25 g of samples were added to 225 ml of 0.85% aseptic physiological saline and the mixture was homogenized aseptically. After a serial dilution (10−1 to 10−5) in sterile saline, every 1 ml of the dilutions was inoculated into the selective agar medium. Plates were incubated at 37 °C for 48 ± 2 h to determine total aerobic viable count (TAVC) and Escherichia coli values. For counting mold and yeast, they were incubated at 28 °C for 5 d.

Determination of pH value

-

The pH value was determined by using a pH meter (Fisher Scientific, AB150) according to the method of Aregbe et al.[9]. Ten g of noodles was added into 90 ml distilled water and was ground into a uniform suspension with a grinder (SMF2002, Supor Appliance Manufacturing Co., Ltd, Nanjing, China). A pH meter was then used to measure the pH change of samples during the storage time.

Sensory evaluation

-

The sensory evaluation of wet KGM noodles was performed as previously described by Lin et al.[10] with few modifications. Fifteen trained panelists were invited to evaluate the samples based on five main aspects: appearance, color, texture, smell and taste, and overall acceptability. The highest score of sensory score was 10 points, and the lowest score was 1 point. The evaluation results were calculated by the arithmetic mean value. When the score was less than 5, the product sensory was determined to be unacceptable. Specific evaluation indicators are shown in Supplemental Table S1.

Texture measurement

-

The textual properties of KGM noodes were obtained using a Texture Analyzer (TMS-PRO, FTC, USA) equipped with PLUS physical property tester according to the description of Zhao et al.[11]. In brief, operating conditions were used as followed: an aluminum cylindrical probe (SMP P/36R) and 0.05 N of the trigger force. Besides, the rate before and after the test was 1 mm·s−1, while the test speed was 2 mm/s. The shape variable was set to 50%. The compression distance was fixed at 15 mm. As results, the hardness, elasticity, cohesion, and chewability of each sample was determined.

Determination of color difference

-

The method of Lu et al.[12] was adopted with slight modification. Samples were placed in clean plates, the color difference meter (Nh300, Shenzhen Sanenshi Technology Co., Ltd, Shenzhen, China) was calibrated in black and white with a calibration plate. Then the light source was placed directly above the sample to test the values of L* (brightness), a* (redness), and b* (yellowness). Each sample was tested at three random sites.

Determination of moisture content

-

The aluminum cassette was dried to a constant weight (m1). The 5 g sample (m0), which was laid flat on the bottom of the weighing box, was dried for 4 h and placed in a drying dish until it cooled to room temperature before being weighed (m2). The average value of three parallel sets of each sample was calculated as the moisture content of the sample (W%).

$\rm W{{\text{%}}} =\frac{{m}_{1}+{m}_{0}-{m}_{2}}{{\text{m}}_{\text{0}}}\times \text{100} $ Scanning electron microscopy (SEM)

-

Samples after storage for 8 weeks were used to characterize the morphology of KGM noodles. Samples were quickly frozen by the liquid nitrogen and coated with a fine layer of gold in a vacuum evaporator. Under the acceleration voltage of 10.0 kV, the cross-sections of samples were monitored at 1000× and 3000× by SEM (Zeiss EVO LS10, Carl Zeiss AG, Jena, Germany) following the previous study of Fang et al.[13]. The magnification of each micro-image was recorded in the figures.

Statistical analysis

-

IBM SPSS Statistics 20 software (IBM, USA) and SAS software were used to calculate the mean and standard deviation. One-way ANOVA (Duncan's test) (p < 0.05) was applied for the univariate experimental statistical analysis. Origin 2018 (Origin Lab Company, USA) was used for drawing. Unless stated otherwise, all tests were carried out in triplicate.

-

FromTable 2, only changing the pH of wet konjac noodles cannot effectively control the microbial growth. As presented in CA treatment, the total colony count reached to 5.83l g CFU·g−1 after storage for 6 weeks, which lost its marketability, though it performed a better result during the first 2 weeks of storage than that of CK group. The results of detected E. coli and mold/yeast showed a similar situation. However, compared with no resistance growth of a single acid soaking treatment against mold/yeast, it showed an effect on growth inhibition to E. coli. By contrast, after equipped with pasteurization and vacuum packing based on the acid soaking or alkali immersion, the growth of total colony, E. coli, and mold/yeast was significantly inhibited, which was far below the limit of standards throughout the storage time. Our results demonstrated that acid or alkali immersion combined with heat sterilization and vacuum packing could effectively extend the shelf life of wet konjac noodles and meet the requirement of microbial indicators. As the main cause of deterioration and corruption of fresh staple food was the proliferation of microorganisms, mainly the bacteria and fungi[14,15], the treatment of CI and CF groups displayed efficacious ways to combat the growth of spoilage organisms.

Table 2. Microbial level of wet konjac noodles with different treatments.

Level

(lg CFU·g−1)Groups Storage time (w) 0 1 2 4 6 8 10 Total colony CK <1 2.26 ± 0.08d 5.33 ± 0.03c 5.66 ± 0.03a 5.28 ± 0.07b − − CA <1 1.17 ± 0.01f 1.54 ± 0.02e 2.57 ± 0.04d 5.83 ± 0.08a 4.97 ± 0.08c 5.01 ± 0.04b CF <1 <1 <1 <1 <1 <1 <1 CI <1 <1 <1 <1 <1 <1 <1 E. coli CK <1 1.02 ± 0.05c 1.66 ± 0.07b 1.85 ± 0.06a 1.87 ± 0.07a − − CA <1 <1 1.17 ± 0.08b 1.16 ± 0.01b 1.41 ± 0.07a 1.20 ± 0.06b 1.33 ± 0.03a CI <1 <1 <1 <1 <1 <1 <1 CF <1 <1 <1 <1 <1 <1 <1 Mold/Yeast CK <1 1.11 ± 0.28c 2.46 ± 0.37b 3.75 ± 0.04a 2.64 ± 0.02b − − CA <1 1.07 ± 0.11f 2.26 ± 0.20e 3.63 ± 0.16d 4.28 ± 0.15c 4.66 ± 0.06b 4.99 ± 0.03a CI <1 <1 <1 <1 <1 <1 <1 CF <1 <1 <1 <1 <1 <1 <1 Different lowercase letters represent significant differences of the same treatment during the storage time (p < 0.05); < 1 means that no microorganisms were detected in the culture medium; and '−' means that samples are not detected. Effects of different storage methods on sensory quality

-

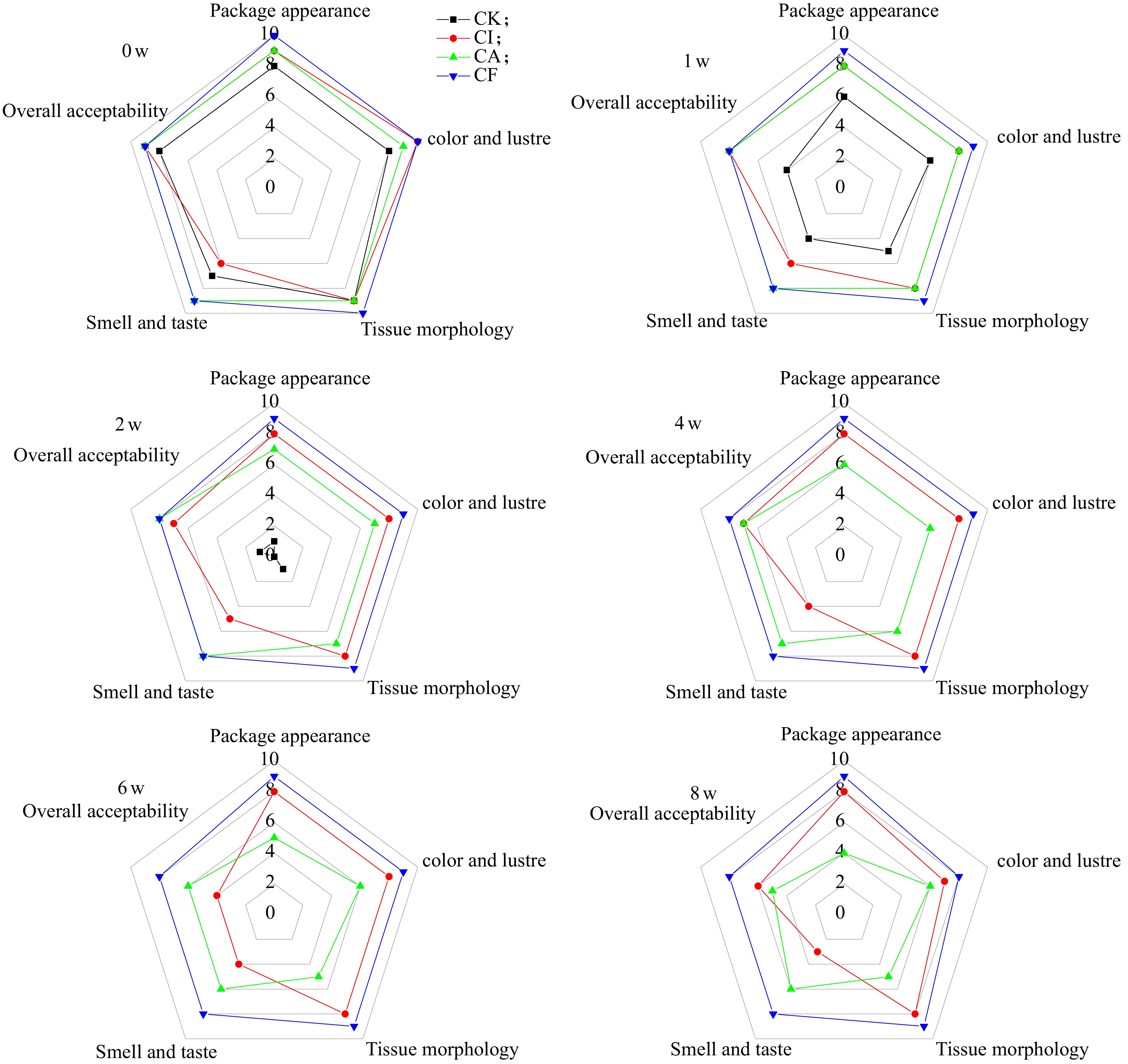

The changes in sensory properties of wet konjac noodles in different treatment groups during storage are illustrated in Fig. 1. Compared with the CK group, the three treatment groups displayed a better sensory characteristics during the storage period. Among them, the fresh-keeping period of the sample was effectively extended by CF group. At the beginning of storage, all samples had strong elasticity and rigidity, crisp but not soft, white color and uniform luster. However, after storage for 1 week, CK group first became unacceptable in general, and samples were corruption symptoms that could be detected by eyes. To be specific, the color of the CK group was slightly yellow and appeared some bubbles on the surface. After a 4-week storage, the quality of the CA group decreased significantly and was evaluated as an unacceptable state, showing an obvious juice exudation and loose tissue. By contrast, CF and CI treatment groups were still in an acceptable state. Compared to CI group, CF group obtained a higher score based on the significantly better performance of tissue morphology and color, while there was no significant difference in packaging appearance. Overall, the CF treatment received the best evaluation result of sensory characteristics.

Figure 1.

The change of sensory characteristics (appearance, color, texture, smell and taste, an overall acceptability) of wet konjac noodles with different treatment methods during storage.

Effects of different preserving methods on pH

-

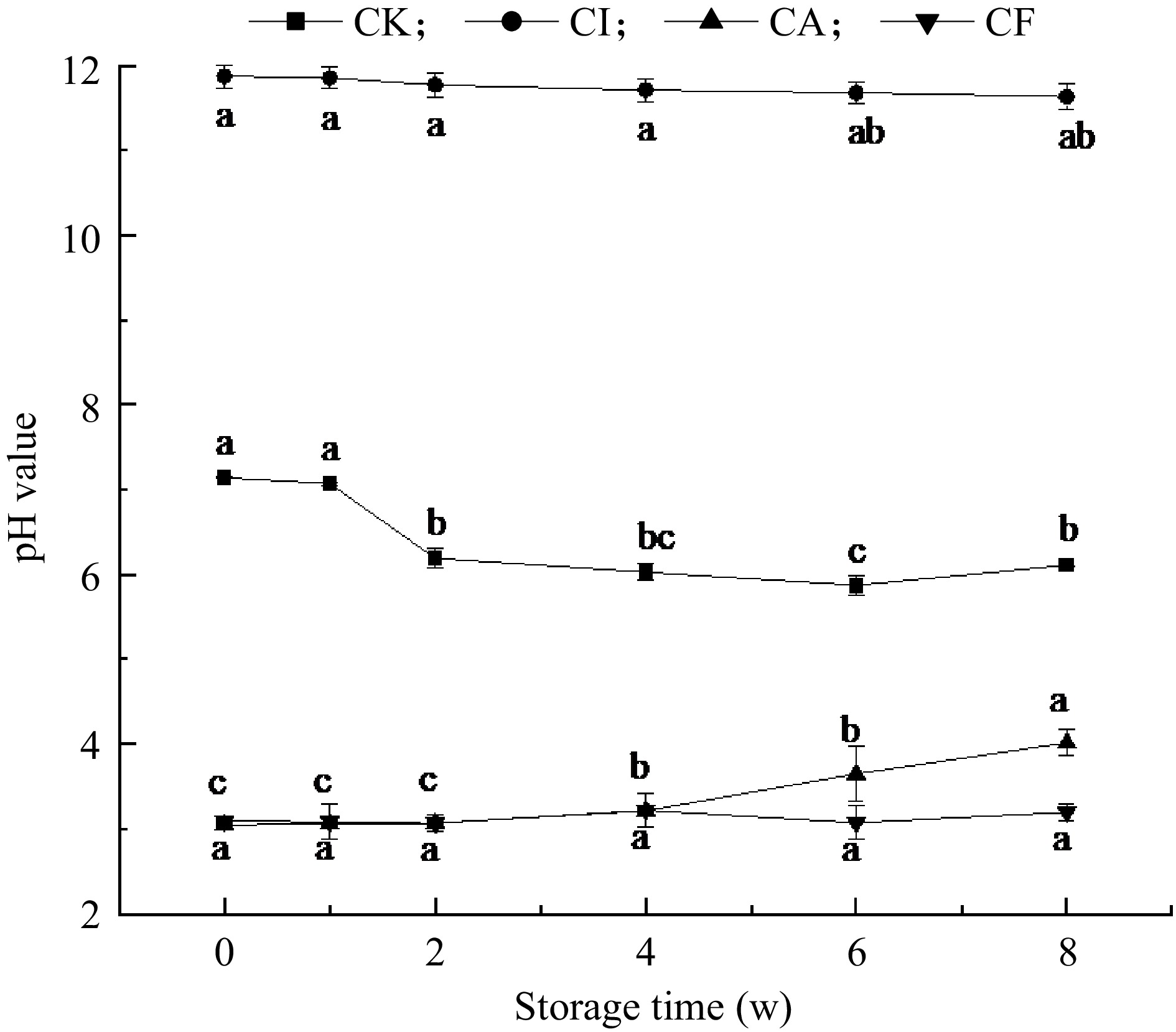

The pH change tendency of wet konjac noodles during storage is shown in Fig. 2. Initially, the pH value of the CK group decreased sharply after storing for 1 week and the trend continued with the increase in storage time, which was mainly due to the influence of microbial activities. Besides, after changing from neutral to week acidic state at about 6.0, it remained stable. In contrast, the pH value of CI group was quite stable during storage, but was slightly lower than the initial value with no significant change. However, the pH value of the CA group samples exhibited an obvious increase during the storage time and the samples deteriorated in the last two weeks, resulting in the pH value rising to 4.0. Studies proved that metabolites generated by spoilage microorganisms would change the pH value of food[16]. Finally, the CF group presented the most stable of pH value during storage among all the treatments.

Figure 2.

Effects of different preserving methods on pH of wet konjac cold noodles during storage. Different letters indicate significantly different at p < 0.05

Effect of different preserving methods on texture properties

-

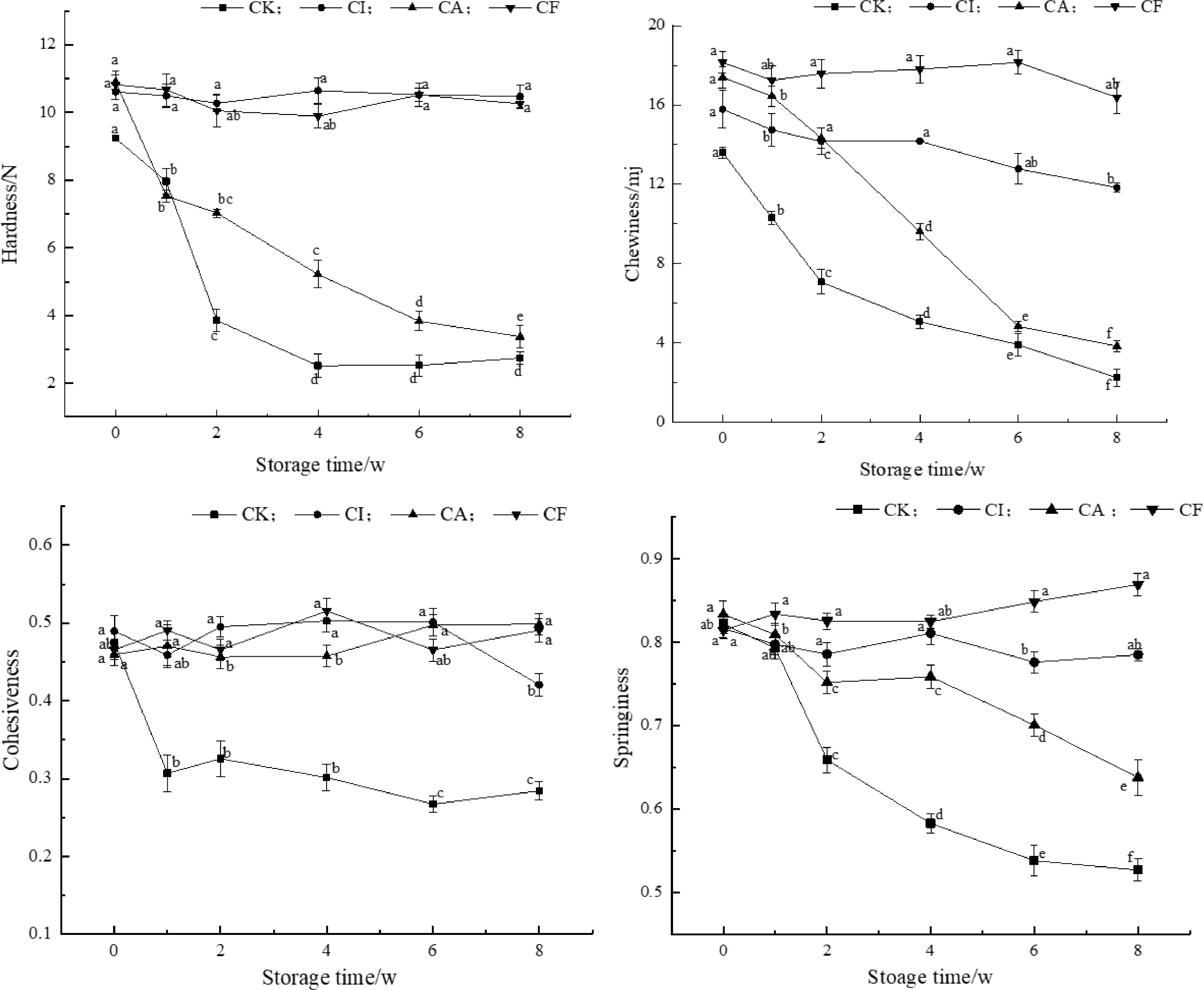

Changes in internal structure of wet konjac noodles during storage are shown in Fig. 3. The testing method could visually reflect the taste features of samples during consumption. In general, different treatments had significant influence on texture indexes except for cohesion. To be specific, in the CK group, its hardness, chewability, and elasticity decreased significantly in the second week, which might be due to the peak count of microorganisms. As a result, the product lost its commerciality. Compared with the CK group, the hardness, chewability, and elasticity of the CA group were significantly improved at the end of storage, indicating that the quality of wet konjac noodles during storage could be enhanced by the acid soaking treatment. Studies proved that the proliferation of microorganisms during storage could destroy the gel network structure, resulting in a decrease in hardness and poor quality of cold noodles[5]. The change of elasticity might also be due to the migration and loss of water. What's more, there was no significant difference in hardness, chewability, and elasticity between the CI group and CF group, indicating that the composite treatment could maintain the texture properties of wet konjac noodles. Overall, the index of the CF group was better than CI group, indicating that the acid soaking treatment was superior to alkali immersion based on the same treatment of pasteurization and vacuum packing.

Figure 3.

Effects of different preserving methods on the texture properties of wet konjac noodles during storage. Different letters indicate significantly different at p < 0.05.

Effects of different preserving methods on the color difference

-

Changes of color difference of wet konjac noodles during storage are shown in Table 3. The L* value of CK group decreased sharply from 56.62 at the beginning of storage to 44.95 at the end of storage. Besides, the a* value was slightly decreased from 1.16 to −0.48 during storage, while b* value was increased from 4.25 to 6.54 at the end of storage. As observed visually, the sample changed from bright white to light yellow throughout the storage period. In the CA group, its chromaticity was relatively stable without significant difference initially, but changed significantly from the second week of storage. In contrast, L*, a*, and b* values of CI and CF groups were quite stable without significant changes. Interestingly, a significant difference was found in the L* and a* values of noodles between CA group and CF group in the later stage of storage, which was hard to identify from sensory evaluation. At the same time, it was found that the L* value of the CI group was significantly different from that of the CF group during storage, indicating that pH had a greater impact on the whiteness of wet konjac noodles. In addition, the significant difference in b* value between them in late storage might be due to the influence of different ions to the yellowness.

Table 3. Relationship between L*, a*, b* value and storage of different treated samples.

Parameters Groups Storage time (w) 0 1 2 4 6 8 L* CK 56.62 ± 1.33aB 54.66 ± 0.23bC 50.61 ± 1.02cD 47.74 ± 1.78dB 45.12 ± 1.71eC 44.96 ± 0.87eC CI 54.98 ± 0.55aC 54.20 ± 0.84abC 54.77 ± 0.58aC 53.03 ± 0.85abC 52.16 ± 0.95bB 53.43 ± 0.64abB CA 58.03 ± 0.34aB 58.30 ± 0.49aB 57.24 ± 0.95aB 53.62 ± 1.14bC 53.27 ± 1.16bcB 51.91 ± 1.43cB CF 60.02 ± 1.15aA 61.66 ± 0.37aA 60.52 ± 0.70aA 61.13 ± 0.87aA 61.91 ± 1.80aA 61.87 ± 1.89aA a* CK 1.16 ± 0.32cA 0.08 ± 0.14bA 0.75 ± 0.33aA −0.17 ± 0.26bA 0.04 ± 0.64bA −0.48 ± 0.48bA CI −1.03 ± 0.06bA −1.80 ± 0.30cC −1.15 ± 0.39bB −0.47 ± 0.10aAB −1.38 ± 0.22bB −1.07 ± 0.100bB CA −1.28 ± 0.43abcA −1.44 ± 0.38bcC −1.36 ± 0.22abcB −0.88 ± 0.19aC −0.98 ± 0.37abB −1.60 ± 0.26cC CF −1.34 ± 0.22aA −0.79 ± 0.44aB −1.35 ± 0.73aB −0.63 ± 0.31aBC −0.87 ± 0.56aB −0.59 ± 0.40aAB b* CK 4.25 ± 0.10cA 4.65 ± 0.32cA 5.40 ± 0.77bA 5.88 ± 0.34abA 6.41 ± 0.31aA 6.54 ± 0.44aA CI 3.94 ± 0.37abA 3.87 ± 0.52bB 4.43 ± 0.11aB 4.22 ± 0.11abB 4.32 ± 0.18abBC 4.30 ± 0.25abBC CA 4.23 ± 0.39bcA 3.94 ± 0.36cB 3.89 ± 0.53cB 4.18 ± 0.03bcB 4.73 ± 0.16abB 4.87 ± 0.47aB CF 3.97 ± 0.58aA 4.04 ± 0.18aB 4.05 ± 0.17aB 3.87 ± 0.66aB 3.82 ± 0.71aC 3.93 ± 0.42aC Different lowercase letters represent significant differences in data in the same row (p < 0.05); different capital letters represent significant differences in data in the same column (p < 0.05). Effects of different preserving methods on moisture content

-

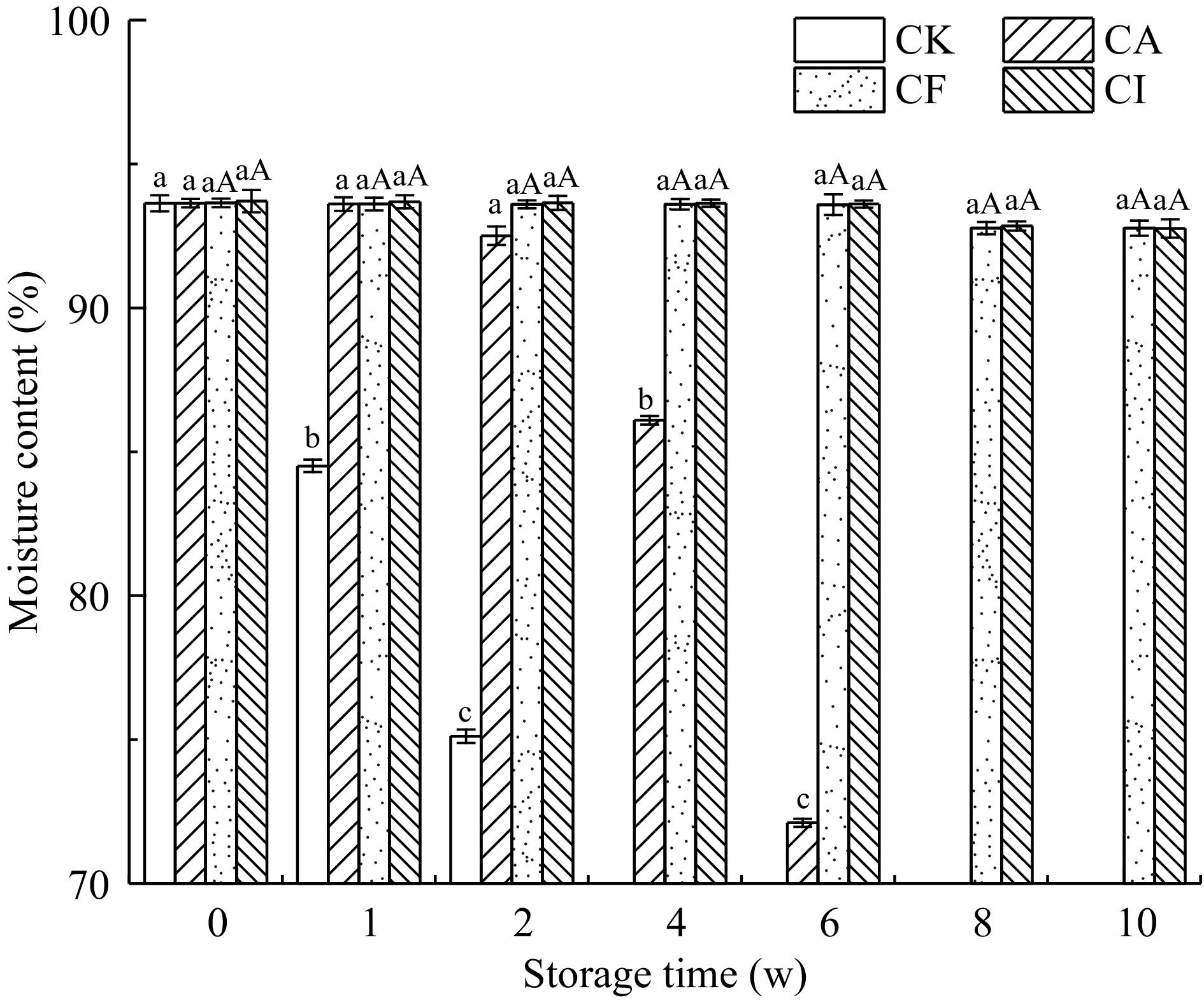

As konjac cold noodles belong to high moisture foods, the moisture change during storage plays an important role in the product quality. The longer noodles can maintain a high level of water, the longer a high quality of product is presented. As displayed in Fig. 4, the moisture content of CK and CA groups decreased rapidly after spoilage. However, CF and CL groups could hold a high moisture content throughout the storage period, and there was no significant difference between them. In general, our samples could have a good water holding capacity after the compound treatment, regardless of acid soaking or alkaline immersion.

Figure 4.

Different preserving method effects on the moisture content of wet konjac cold noodles during storage. Different lowercase letters indicate significant different at p < 0.05 in the same group at different storage times; Different capital letters indicate significant different at p < 0.05 between different groups during the same storage time.

SEM results of wet konjac noodles with different preserving methods

-

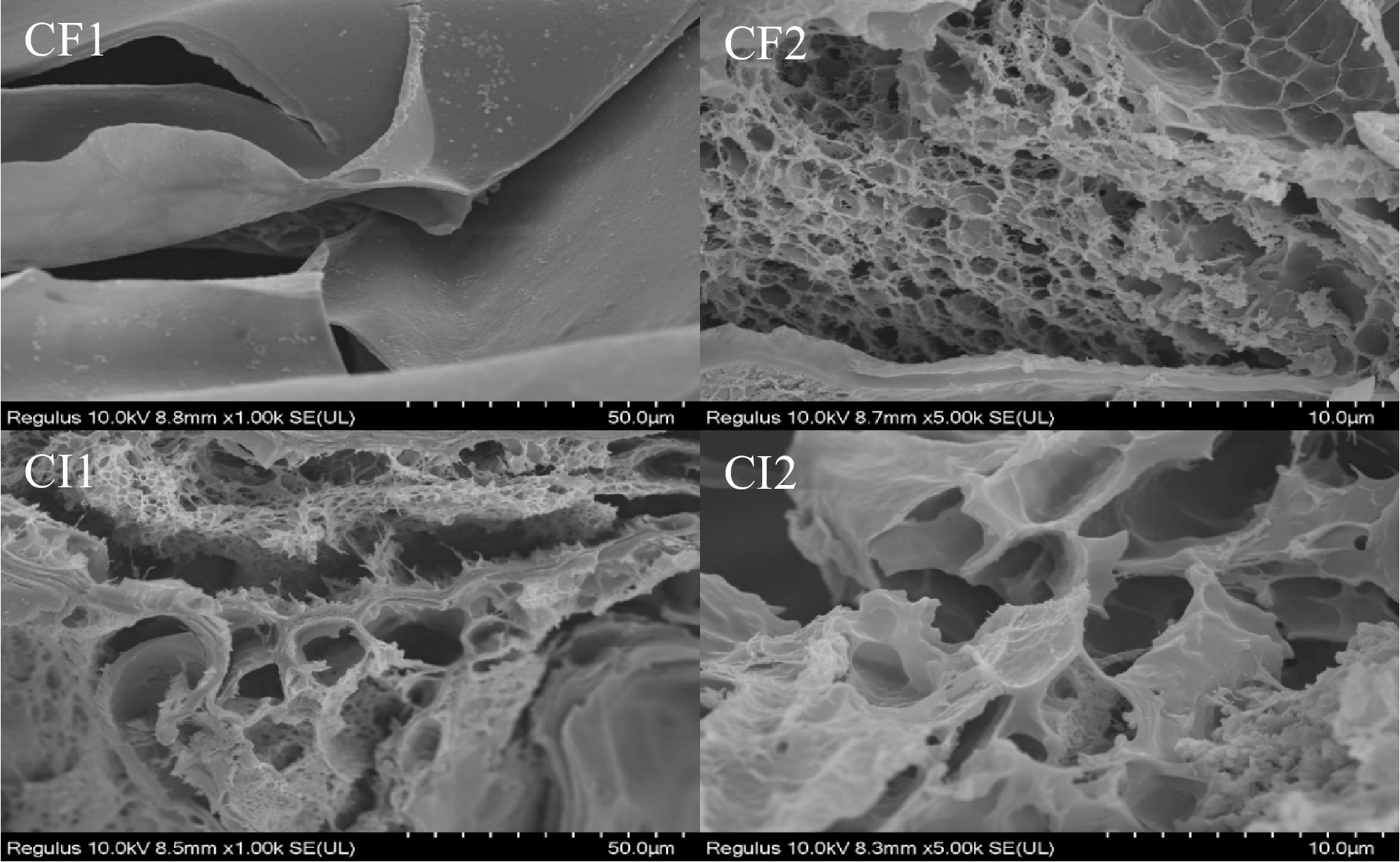

Finally, the SEM was used to present the internal microstructure of CF and CI groups based on their better performance than other treatments. As displayed in Fig. 5, noodles after storing for 10 weeks were used and differences in the microstructure of the gel system were observed between these two groups. To be specific, the surface of the CF group was relatively smooth, the internal structure was compact, and the internal pores were relatively uniform, like a 'honeycomb', showing a relatively dense porous network structure (Fig. 5). The surface of the CI group was relatively rough, and many folds were observed. At the same time, the internal structure was relatively loose and unevenly distributed with larger pores and slight fractures (Fig. 5).

Figure 5.

Micro-images of a cross-section of wet konjac noodles in CF and CI groups. CF1 and CI1 are shown at the scale of 50.0 μm, while the CF2 and CI2 are shown at the scale of 10.0 μm.

Data availability statement

-

The data that support the findings of this study are available from the corresponding author or submitting author upon reasonable request.

-

Wet konjac noodles are vulnerable to microbial contamination due to their high moisture content. In this study, cost-effective methods were developed to preserve the noodles. Specifically, when the noodles were soaked in either acid (pH = 3) or alkaline (pH = 12) solution followed by pasteurization and vacuum packing, the microbial growth was strongly inhibited, and the pH values and moisture content had no significant change throughout storage for 10 weeks. However, compared to the CI group, the CF group obtained more desirable results in whiteness, sensory characteristics, texture properties, and internal microstructure. Therefore, we think CF treatment is suitable for fresh-keeping of wet konjac noodles and is promising for industrial application.

The microbial proliferation in konjac cold noodles could be effectively repressed by both alkaline immersion and acid soaking. The antibacterial mechanism of alkaline immersion might be related to calcium hydroxide, which acted as the acidity regulator in packaging. Ca2+ had a high charge density and had strong electrostatic binding with water molecules, thus reducing the content of free water[17]. As for acid soaking, citric acid might change the internal environment of bacterial cytoplasm after penetrating the plasma membrane of bacterial cells, resulting in the decomposition of cytoplasm and the depletion of adenosine triphosphate (ATP) in bacterial cells[18−20]. However, single acid soaking treatment could not inhibit the microbial growth over 1 week. Therefore, it is imperative to deal with the noodles together with other anti-corrosion measures. Heating can inactivate microorganisms by coagulation or denaturation of intracellular enzymes[21]. Vacuum packaging can not only repress microbial proliferation, but can also extend the sensory quality of konjac cold noodles by isolating oxygen[22]. This study showed that the comprehensive use of acid soaking, pasteurization, and vacuum packaging could inhibit the growth and reproduction of bacteria, molds, yeast, and other microorganisms. Corresponding to the repressed microbial activity, the pH value of the product was stabilized.

Sensory evaluation is an important index to directly reflect consumers' purchase intention[23]. As a high moisture gel product, the sensory stability of konjac cold noodles during storage is not easy to retain. Water precipitation would be inevitable due to the formation of more hydrogen bonds after the removal of acetyl groups by KGM[3]. Our study found that the water holding capacity of konjac cold noodles could be retained by CF treatment, although a small amount of water precipitation still occurred. The inflated bag phenomenon in the CK group might be caused by the reproduction of gas-producing microorganisms. The color of CA group would change from white to light yellow after 4 weeks storage, which was related to the increased concentration of soy protein isolate as the precipitation of water in samples. Good water retention is also beneficial for the elasticity of the cold noodles[24] and it was well realized by CF treatment On the other hand, there were some bubbles in the product, which might be related to the fast rotating speed during the mixing process so that a certain amount of air was dissolved in the water. Compared to traditional alkaline preservation, treatment by acid soaking was more favored by consumers in terms of smell and taste.Studies have shown that the surface of the cold noodles after acid soaking was smoother and more conducive to savoring[14]. In general, the sensory quality of wet konjac noodles was better in acid soaking than immersing in an alkaline solution.

It was well known that the pH value of the system would be changed by microbial metabolism. Studies also proved that the change in pH was related to water content and storage temperature[25,26]. It could be clearly seen from the CK group that the pH values was more significant decreased as the cold noodles started to corrupt because of the production of acidic metabolites by spoilage microorganisms[16]. In addition, storage temperature would also affect the growth and reproduction of microorganisms, resulting in changes in pH[27]. A low pH value would not only produce an acidic environment but also change the sensory flavor. According to the sensory evaluation results, the low pH environment caused by citric acid did not significantly affect the edible taste of konjac composite cold noodles. Therefore, it further demonstrated that the CF group was more conducive to maintaining the quality and flavor of cold noodles during storage.

The texture characteristics help to reflect the taste of cold noodles in the consuming process. With the extension of storage time, the texture of samples in CK group changed considerably. This phenomenon showed that changes would occur between water and wet product components. Product hardness was affected by the combination of water and non-aqueous components[28]. The migration of water changed its hardness. Our results showed that the hardness increased during storage and remained stable storage after CF and CI treatments. In the comparison of these two treatments, the alkali immersion could enable the cold noodles to be wrapped in the liquid, so that the moisture content of the whole system was high. There was no liquid around the cold noodles after acid soaking, and the elasticity of the cold noodles was increased to a certain extent after the slow precipitation of water. Generally, the more elastic the cold noodles were, the better the taste. The three-dimensional network structure formed by KGM, soy protein isolate, and starch particles could play a great role in wrapping water molecules. During storage, the change in sample chewability might be due to the formation of an insoluble film on the surface of wet konjac noodles[29].

The product color was considered to be a critical determinant of the marketability[30]. For wet konjac noodles, it was largely influenced by the addition of soybean protein isolate, sweet potato starch and konjac flour. Among them, protein content was negatively correlated with cold noodles' color[25]. Research showed that the loss and migration of water in wet food would cause color changes[31]. Our study found that the sample color after acid soaking changed steadily during storage, and the acid soaking treatment could change the chromaticity value of the samples. The b* value of samples treated by acid soaking decreased significantly, indicating that the color was white and transparent compared with the CK group. A bright white appearance was desirable for wet cold noodles, while a yellowish appearance was a negative attribute. On day 0, the L* value of the acid soaking composite treatment group was 60.02, the L* value of the alkali immersion composite treatment group was 54.98, and the L* value of the control group was 56.62. There was a significant difference in L* value between the acid soaking treatment group and the alkali immersion treatment group on day 0, indicating that the acid soaking treatment had a great impact on the improvement of samples. With the increase in storage time, the color change of the CA group and CI group was not significantly different from the initial value, indicating that the acid soaking measures could well maintain the color of wet konjac noodles.

The network structure of wet konjac noodles was mainly composed of KGM, soybean protein isolate, and sweet potato starch, which were superimposed and interacted with each other to form a relatively dense and stable three-dimensional network structure[32]. The sample treated by acid soaking could maintain a denser structure during storage, and the porous structure could reduce water loss to a certain extent. In contrast, the sample immersed in the alkaline solution had a loose structure during storage, which might affect the taste of the cold noodles. It was pointed out that the fluffy honeycomb network of the composite gel system might be the reason for the low hardness of the gel[33].

In conclusion, wet konjac noodles as a novel high-moisture gel food, is produced and investigated in this study. The results showed that the acid soaking combined with pasteurization and vacuum packing could improve the storage stability of wet cold noodles and promote the formation of a tighter network structure between KGM and other properties compared with the traditional preserving methods. In general, this work has reference value for the preservation of high moisture foods.

This research was supported by Jiangsu Agricultural Industry Technology System (JATS-2022-476).

-

The authors declare that they have no conflict of interest.

- Supplemental Table S1 Evaluation standards for sensory quality of wet konjac noodles.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

He L, Chen B, Chen Z, Cai H. 2023. A cost-effective method for preserving wet konjac noodles based on hurdle technology. Food Materials Research 3:17 doi: 10.48130/FMR-2023-0017

A cost-effective method for preserving wet konjac noodles based on hurdle technology

- Received: 24 February 2023

- Accepted: 22 May 2023

- Published online: 07 August 2023

Abstract: This paper aims to investigate the effects of several novel preserving methods on the quality of wet konjac noodles during storage. Wet konjac noodles were prepared by konjac flour, soy protein isolate and sweet potato starch. Fresh-keeping treatments by single acid (pH = 3) soaking (CA group), acid soaking followed by pasteurization and vacuum packing (CF group), and alkaline immersion followed by pasteurization and vacuum packing (CI group) were set. As a result, CF and CI groups could well inhibit the growth of microorganisms during storage at room temperature (28 ± 1 °C) for 8 weeks. The treated wet konjac noodles also had stable sensory quality, better odor and taste, and higher chewiness and elasticity compared with the control (CK) group. Compared to CI treatment, CF treatment exhibited more desirable performance in whiteness, sensory characteristics, textural properties and internal microstructure of the product. In summary, the use of acid soaking followed by pasteurization and vacuum packing technology is an efficacious way to ensure the expected shelf life of wet konjac noodles. This technology could also provide some theoretical and technical support for enterprises to process and produce wet konjac noodles and other high moisture foods.

-

Key words:

- Preserving technology /

- Wet konjac noodles /

- Microorganisms /

- Sensory quality