-

Fresh foods such as fruits, vegetables, meat, poultry, fish and other agricultural products have a moisture content of 60-90%, and their water activity is generally between 0.98 and 0.99[1−3]. Their rich proteins, lipids, carbohydrates, dietary fiber, vitamins and a series of micro-nutrients necessary for a healthy life are suitable for microbial growth. And the action of some biological enzymes, which cause food spoilage and some poisonous substances may be produced[4]. Drying and dehydration can significantly reduce the moisture content and water activity in food, weaken the enzyme activity and inhibit the growth of microorganisms, thus increasing the stability of food quality in the storage process to a certain extent. With the extension of shelf life and the reduction of product volume, the storage and transportation of dried food is more convenient and faster. In addition, dried foods are more attractive to some consumers than fresh foods. For example, dried mushrooms have better flavor and aroma than fresh mushrooms, and beef jerky has better flavor than fresh beef.

The most commonly used drying methods include hot air drying, vacuum drying, heat pump drying, microwave drying, infrared drying, freeze drying, and fluidized bed drying[5,6]. With the exception of freeze-drying and vacuum drying, these drying methods apply heat to the product by conduction, convection or radiation, enhancing the efficiency of moisture exchange between the material and the external environment. Despite this, their mechanisms invariably point to the reduction of the external mass transfer resistance and the increase of the heat transfer rate, while the optimization of the internal structure and internal mass transfer resistance of the material is not obvious[7]. For that purpose, some pretreatment methods are considered to modify the internal structure of the material.

The objective of pretreatment is mainly to accelerate internal moisture migration, reducing drying time and improving the quality of the dried material[8]. Drying directly without pretreatment probably leads to a long drying time, uneven water loss, unacceptable color and terrible flavor[9,10]. Conventional pretreatment methods include chemical solution treatments (hypertonic, alkaline, sulfite and acid etc.), gas (sulfur dioxide, carbon dioxide and ozone) and blanching (hot water, steam, superheated steam, ohmic and microwave heating, etc.) treatments[11]. Although these pretreatments proved to have a positive impact on reducing drying time and improving the drying process, the treated materials may also suffer from chemical absorption, solid phase loss, poor rehydration, structural collapse, quality deterioration, etc., especially during long drying times[12].

Many studies have shown that non-thermal processing techniques have the least negative impact on food quality. In this sense, some non-thermal sterilization techniques such as cold plasma (CP), ultrasound (US), and pulsed electric field (PEF) were widely investigated as pretreatment for drying agricultural products and meat[13−15]. The development and application of these new pretreatment technologies could not only improve moisture distribution and reduce energy consumption, but also further improve the functional and nutritional properties of dried products. In terms of retention of heat-sensitive components, such as vitamins, phenol, carotenoids and omega fatty acids, these technologies perform significantly better than the traditional pretreatment and untreated samples[16]. High quality dry products are obtained by modifying tissues and cells to promote permeability, dehydration and release of cellular components in a non-thermal process. The quality of food products is well maintained because the temperature difference within the product is small compared to the temperature difference during the heat treatment[17]. Therefore, the investigation of non-thermal pretreatment before drying is a hot topic at present.

In view of this, this paper aims to provide a broad, qualitative and quantitative overview of the positive effects of new non-thermal pretreatment on improving drying kinetics, enchancing product drying performance and reducing nutrient loss in agricultural products and meat processing. The applications and limitations of these new pretreatment technologies are also described in detail and their future perspectives are speculated.

-

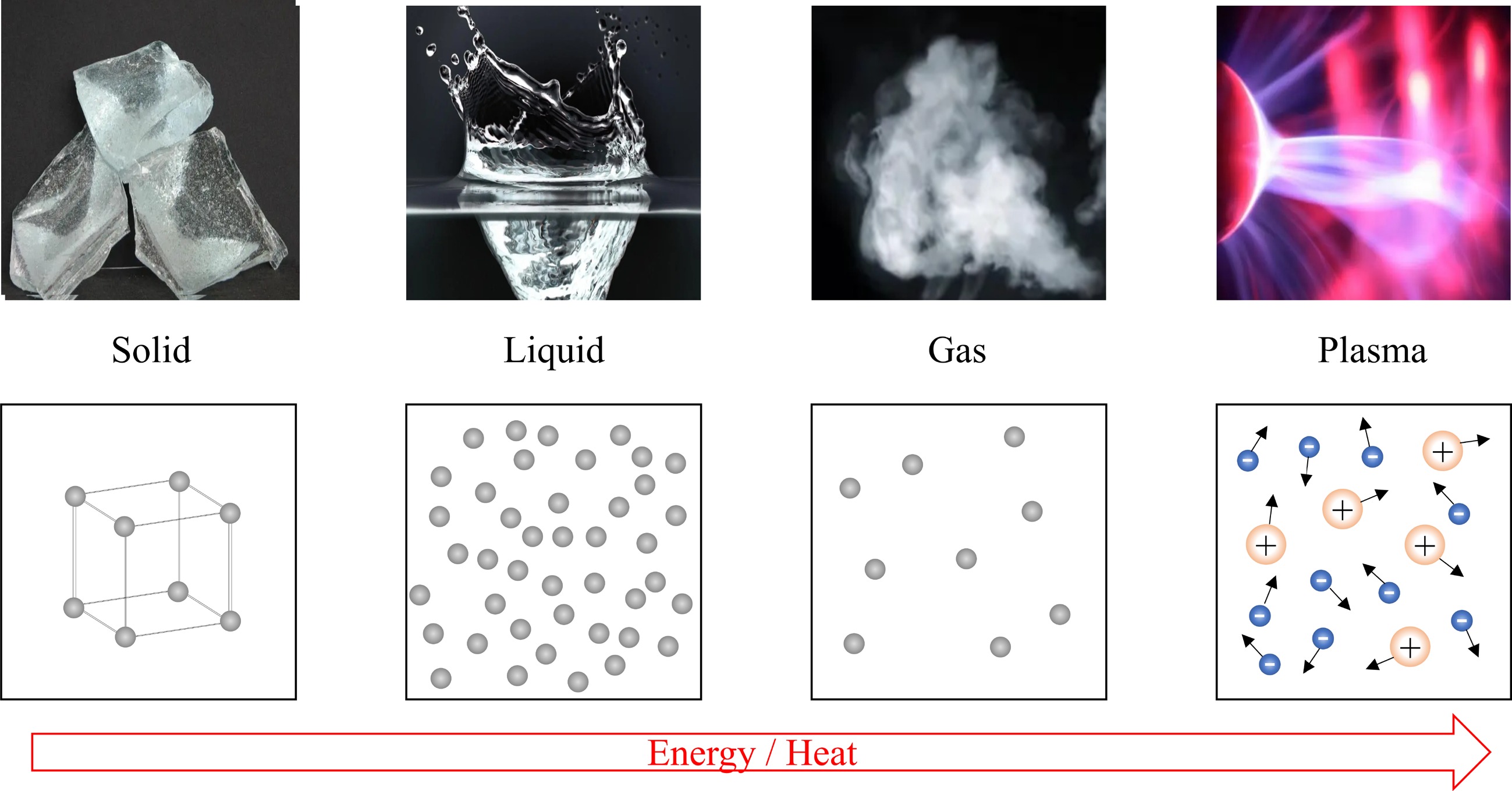

Plasma is considered to be the fourth state in which substances other than solids, liquids and gas exist, as shown in Fig. 1. Plasma is electrically neutral as a whole and consists mainly of electrons, positive ions, negative ions, free radicals, excited or non-excited gas molecules and photons in the ground or excited state[18], which mainly includes two categories, namely thermal (equilibrium) and non-thermal (non-equilibrium) plasmas. In non-thermal plasma (also called low temperature or cold plasma), the applied energy causes elastic collision among gas molecules, atoms and electrons, which accelerates the transfer of kinetic energy between particles. In this case, some heavy particles such as ions, neutral molecules and atoms transfer energy faster than electrons. Therefore, electrons are at a high temperature of 1 to 10 eV, while neutrons, ions and free radicals are still close to room temperature[19]. Higher electron temperature and lower heavy particle temperature make the whole system appear low temperature and non-equilibrium state, so it would not impose extreme conditions on the sample[20].

Air, oxygen, nitrogen, helium, argon and mixtures of various gases are used to produce CP, among which air is more advantageous due to its easy availability and low cost[21]. The CP produced by air excitation contains various active substances, including reactive oxygen species ROS (such as superoxide anion

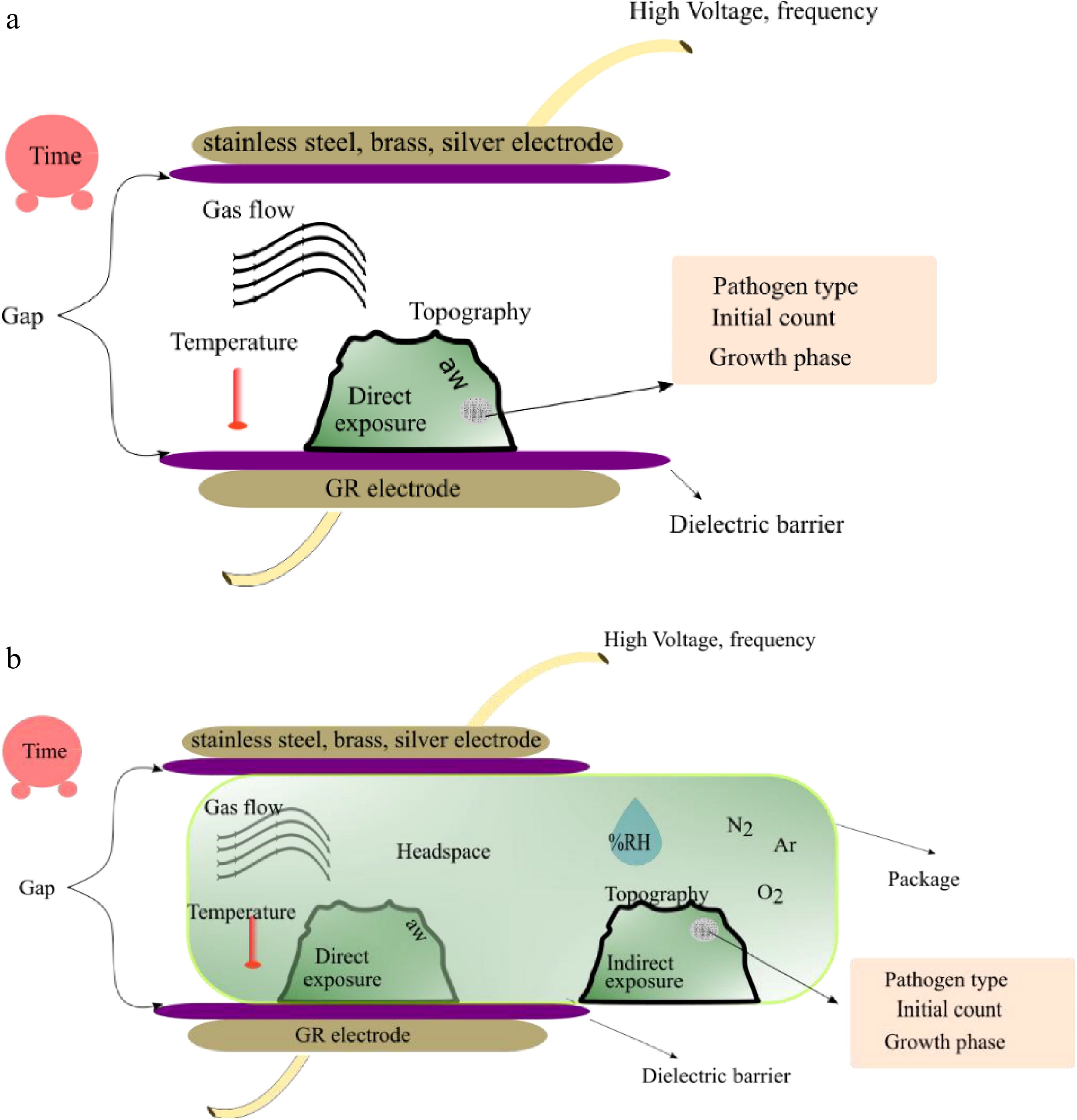

${\text O}_2^- $ The generation of CP can be achieved at atmospheric and/or lower pressure conditions, thus allowing continuous processing, which is an obvious advantage of food processing applications. According to different excitation modes, atmospheric low temperature plasma can be divided into microwave discharge (MD), radio frequency discharge (RFD), glide arc discharge (GAD), corona discharge plasma (CDP) and dielectric barrier discharge (DBD), among which DBD is one of the most widely used plasma generating devices[29]. In possession of simple operation, mature technology and high efficiency, the treatment effect of DBD equipment is not affected by temperature, gas flow rate and other factors[30]. Due to the existence of one or more insulation layers (dielectric barrier) in the current path between the two metal electrodes of DBD, as shown in Fig. 2, spark or arc discharge can be avoided, thus generating uniform and stable discharge and plasma. In addition, the existence of insulating layers prevents the electrode from directly contacting the discharge gas, avoiding the corrosion of the electrode. The choice of insulation material is also common, usually using glass or silica glass, ceramic materials, mica and thin enamel or polymer layers[31]. In order to ensure the stability of the discharge, the distance between the two electrodes is limited to a few millimeters, and a sinusoidal or pulsed high voltage power supply is required to achieve atmospheric discharge. In addition, DBD equipment was also tested for the processing of food materials in packaging. However, the current research is only limited to foodborne pathogens, spores and aerobic medium-temperature microorganisms on the food substrate, such as Escherichia coli, Salmonella enteritidis, Staphylococcus aureus and Listeria monocytogenes, and proved the effectiveness of the system on microorganisms[32]. Ambient air or modified gas mixtures can be used in packages that are ionizable and can generate and contain a large number of reactive molecules within the package. The ionized state of the gas (called plasma) has an antimicrobial effect and does not affect the integrity of the packaging material[33].

Figure 2.

Basic configuration and treatment of DBD device. (a) Open treatment, (b) packaging treatment.[33]

Application of CP

-

The surface of agricultural products is mostly covered with cuticular wax, which is not conducive to the evaporation of water in the drying process. However, ROS and RNS contained in the CP jet can rapidly bombard and react with the surface of agricultural products, causing the decomposition of waxy skin, thus destroying the waxy layer on the surface and forming etching micropores. This process reduces the hindering effect of surface on internal water migration, increases hydrophilicity and facilitates water evaporation[34]. After treatment of grapes with CP, it was observed that the water contact angle of the surface decreased significantly and changed from highly non-polar to hydrophilic. This also indicates that the decomposition of the cuticular wax on the surface makes the surface of the produce more wettable and permeable[35]. Namjoo et al.[36] investigated the effect of CP pretreatment on the drying of cumin seeds and found that the CP pretreatment significantly improved the effective moisture diffusion coefficient, shortened drying time, energy consumption and color change by changing the surface microstructure of the seeds through the generation of micropores. Scanning electron microscopy (SEM) showed that the cells of tucumã treated by CP at 200 Hz and 800 Hz were deformed seriously and formed larger voids. The drying time was shortened from 270 min to 105 min and 120 min, and the effective water diffusion coefficient increased from 0.9 × 10−7 m2·s−1 to 4.1 × 10−7 m2·s−1 and 4.0 × 10−7 m2·s−1, respectively[37]. The efficiency of plasma etching depends on the rate and concentration of ROS and RNS entering the target object. Therefore, with the increase of treatment voltage, the extension of treatment time and the reduction of spacing, the number of micropores and cracks on the treated surface increased obviously, and the drying rate accelerated significantly. In other words, the degree of plasma etching on the surface is the main factor that determines the effect of accelerated drying.

On the other hand, more and more evidence demonstrated that CP treatment of agricultural products not only changes the surface structure, but also has a significant impact on the microstructure of plant tissue, thus affecting the drying performance. Through scanning tunneling microscope, it was found that the mushrooms treated with CP displayed greater microstructure changes (such as cell disorder, extensive contraction, cell wall rupture or collapse, and increased intracellular voids)[38]. In addition, the main components of plant cell walls are cellulose and pectin, and the different electron ions generated by CP treatment may exert an effect on the covalent bonds between cell wall polymers. In a study on the surface modification of lignocellulose, it was found that CP has strong covalent bond breaking ability, in which nitrogen molecular ions and atomic oxygen cause C4-O covalent bond dissociation and pyranose ring breaking, and finally lead to oxidative degradation of cellulose[39]. Momeni et al.[40] also revealed that the exposure of high methoxy pectin extracted from citrus peels to nitrogen glow discharge plasma resulted in the disruption of pectin side chains and methyl ester bonds, thus altering the network structure of pectin, increasing the characteristic viscosity, decreasing the molecular weight, and decreasing its fracture resistance. The breaking of chemical bonds of cell wall components or the modification of groups caused by CP can reduce the hardness of cell wall and cause voids and cavities in cells, and finally the drying time was shortened.

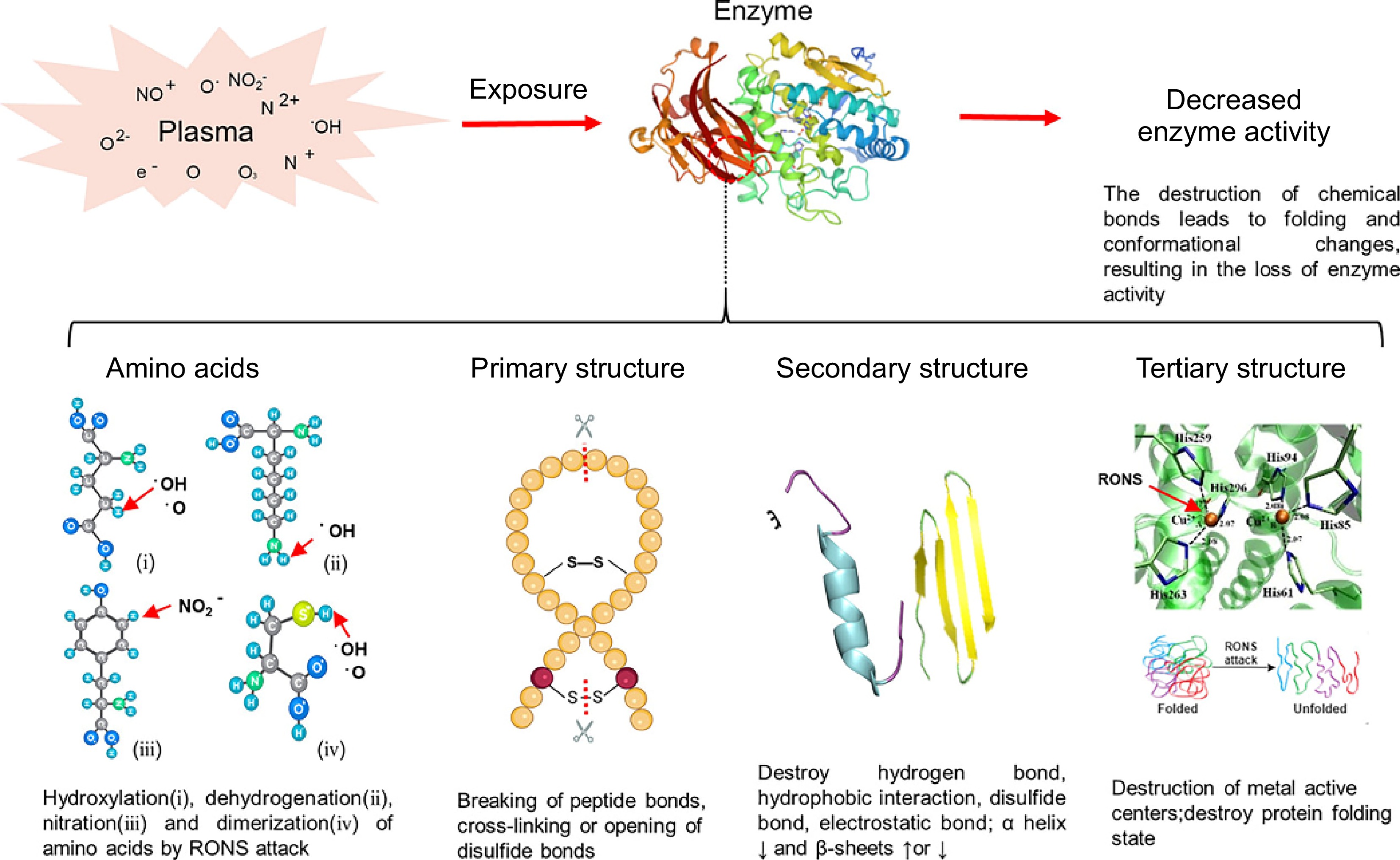

Enzymatic browning (EB) is considered to be the main factor for the decline of product quality (color, phenols content and antioxidant activity) during storage and processing of fruits and vegetables, which is mainly caused by two kinds of food endogenous enzymes: browning enzymes and cell wall degrading enzymes. Browning enzymes include phenylaminolyase (PAL), peroxidase (POD), and polyphenol oxidase (PPO), while cell wall degrading enzymes such as pectinolyase (PL), polygalacturonase (PG), and pectin methyl esterase (PME), both enzymes lead to shorten the shelf life of many fruits and vegetables[41]. On the one hand, the mechanical damage caused by postharvest cleaning, peeling, cutting and transportation of fruits and vegetables creates favorable conditions for the contact between enzymes and substrates, which further promotes the deterioration of quality during drying, such as browning, nutrient decomposition, accelerated oxidation and abnormal flavour[42]. On the other hand, although most enzymes eventually lose their activity under intense drying conditions, it should not be neglected that below the critical temperature, the continuous rise in temperature leads to an increase in enzyme reaction and the change in enzyme activity during the drying process affects the quality of the final dried product. Studies in recent years suggested that CP has a positive effect on the inactivation of browning enzymes and cell wall degrading enzymes. Figure 3 proposed the mechanism of CP treatment affecting enzyme activity. Many studies demonstrated that the inactivation of CP mainly depends on its abundant RNS and ROS[43−45]. Under the attack of ROS and RNS, the conformation and structure of the enzyme changed to some extent. PPO and POD are considered to be the most thermotolerant enzymes among the endogenous enzymes in plants, which are more likely to lead to corruption through biochemical reactions, and are regarded as biological indicators of the effectiveness of heat treatment[46]. However, it was reported that the activities of PPO and POD in banana decreased significantly with the extension of CP treatment time. Although prolonged exposure to CP resulted in an increase in ROS levels in cells, the quinones produced by enzymatic browning decreased after prolonged treatment time, which played a positive role in improving banana surface color[47]. PME is a cell wall binding enzyme, which can de-esterify pectin to produce methanol and pectin with low esterification degree, and then these pectins are further degraded by other pectinases, resulting in tissue softening[48]. Fresh-cut pears were treated with 65 kV atmospheric pressure plasma for 1 min and a significant decrease in POD and PME activity was observed after treatment. Compared with POD, PME showed stronger resistance and slow recovery of enzyme activity[49]. However, some studies also exhibited that the activities of some key antioxidant enzymes[50,51], such as superoxide dismutase (SOD), increased significantly after 60 s of CP treatment at 12 kV and 5 Hz, and displayed a trend of first rise and then drop during storage, which was 15.7% higher than that of the control group on the 20th day of storage[52]. This may be due to the differences in the complexity and stability of protein structure and the diversity of isozymes among different enzymes, resulting in the different sensitivity of different enzymes to CP.

Figure 3.

Mechanism of CP affecting enzyme activity[35].The red dotted line and arrow indicate the position where the plasma exposure destroys the chemical bond. RONS: reactive oxygen species and reactive nitrogen species.

As depicted in Table 1, oxidation, browning and the loss of some active substances were greatly improved with the significant increase of drying rate and the shortening of drying cycle after CP pretreatment. In addition, Bao et al.[53] pretreated jujube slices with CP, and found that compared with the control group, the drying rate and water diffusion rate were significantly improved, and the total phenol content, antioxidant activity, flavonoids and proanthocyanidins content increased by 13.85%, 36.85%, 33.89% and 53.81%, respectively. Zhou et al.[54] found that the L*, a* and b* of dried wolfberry treated with CP were significantly higher than those without pretreament, while the total color difference (ΔE) decreased by 18%−27%. At the same time, microstructural and ultrastructural observations demonstrated that with the prolongation of CP treatment, the cell wall and cell membrane disintegrated, which promoted the release and diffusion of intracellular water and phytochemicals. Many studies found that CP pretreatment can replace traditional chemical pretreatment, solving the problems of additive residues and chemical corrosion[55−57]. As a green alternative, CP can contribute significantly to food security by improving product quality, nutritional value, shelf stability and reducing greenhouse gas emissions.

Table 1. Study on the effect of CP pretreatment on the retention of active substances in the drying process of agricultural products.

Material Conditions Drying method Main results Reference Tucumã 20 kV, 200/500/800 Hz, 10 min

(dielectric barrier discharge)Hot air drying The cells of tucumã treated by CP at 200 Hz and 800 Hz were deformed seriously and formed larger voids. The CP pretreatment improved the concentration of phenolic and antioxidant compounds. [37] Shiitake mushroom 650 W, 135 L·min−1,

10 min

(dielectric barrier discharge)Hot air drying The mushrooms treated with CP displayed greater microstructure changes and preserved higher nutritional attributes (sugars, vitamins, phenolic acids contents and antioxidant activity) compared to the control groups. [38] Whole jujube 5 kV, 650 W, 40 kHz,

1 min

(glow discharge)Hot air drying CP pretreatment significantly changed the surface morphology of jujube, shortened the drying time by 12%, increased the total phenol content by 12%, increased the antioxidant capacity (iron reduction antioxidant capacity) by 11%, and reduced the formation of 5-hydroxymethylfurfural by 15%. [10] Saffron 8 kV, 50 kHz, 15/30/45/60 s

(gliding arc discharge)Hot air drying The sample pretreatment (60 s) with CP reduced the drying time by 54.05% and the energy consumption by 39.52%. 30s pretreatment samples showed significantly higher crocin (12.28%), picrocrocin (19.29%), phenolic compounds (11.33%) and antioxidant scavenging activity (1.76%). [58] Goldenberry 10 kV, 300 W, 50 Hz, 15/30/45/60 s

(gliding arc discharge)Ultrasound-assisted convective drying CP pretreatment lowered the drying temperature from 60−90 °C to 50 °C. The retention of vitamin C, antioxidant activity and total phenolic content increased significantly, and the color retention, storage stability and water absorption capacity were better. [59] White grapes 500 W, 25 kHz, 40 L·min−1

(atmospheric plasma jet)Hot air drying The drying time was reduced by more than 20%, and the total phenol content and antioxidant capacity were increased by more than double. No toxic residues are left, and the product quality is successfully maintained. [60] Shiitake mushroom 650 W, 135 L·min−1,

10 min

(cold atmospheric plasma jet)Hot air drying CP pretreatment significantly altered the surface morphology of shiitake mushrooms, producing intracellular spaces, larger cavities and smaller densities, with reduced activation energy, drying time and energy requirements, and retained the highest amounts of phenolics (463.30 mg/100 g), flavonoids (100.70 mg/100 g) and 2,2-Diphenyl-1-picrylhydrazyl (DPPH) relative inhibitory activity (0.201). [61] Jujube slices 5 kV, 650 W, 40 kHz, 15/30/60 s

(glow discharge)Hot air drying The application of CP significantly changed the surface topography of jujube slice by etching larger cavities, increased the content of proanthocyanidins, flavonoids and phenolic compounds as well. [53] Wolfberry 20 kHz, 750 W, 3 L·min−1, 15/30/45/60 s

(glide arc discharge)Hot air drying CP pretreatment reduced drying time, improved rehydration capacity and color quality, while the retention of phytochemicals varied with the duration of CP treatment. [54] CP can also be used for decontamination or sterilization of equipment and the surface of meat and meat products. However, due to some adverse effects on the color of fresh meat, lipid oxidation and peculiar odor to a certain extent, it is necessary to make a balance between antibacterial effect and sensory quality of products[62]. In terms of drying, there are still no studies on the effect of atmospheric cold plasma on meat drying, which may be due to the difference in structure and composition with plant cells or the compactness and thick width of meat cells. The lower penetration depth of plasma jet is not enough to make meat show a significant increase in drying rate during drying.

Limitations of CP

-

Although various investigations proved the feasibility of CP pretreatment in food processing, its complex ROS and RNS chemistry is challenging in regulatory approval and process verification[63]. On one hand, the diversity of food components (starch, protein, lipids, minerals, vitamins and water) makes the interactions between active substances contained in CP and food materials more complicated, which may lead to unexpected changes in the sensory characteristics of some foods. For example, CP treatment leads to increased lipid oxidation after extended processing time in high-fat foods, such as meat, fish, peanuts, cheese, and oil, due to the oxidation of free radicals (e.g. OH·) during processing[64]. Although CP was able to significantly reduce the number of microorganisms on the pork, more formation of high iron and sulfur myoglobin was observed in the meat by near infrared (NIR) reflectance spectroscopy during the exposure period, resulting in a greenish color of the meat and a greater impact on the sensory quality[65]. It is also difficult to accurately control the equipment parameters because of the different types of materials and throughput[66].

On the other hand, CP is a pilot processing technology, and currently its equipment can only meet the laboratory research of the mechanism. Its large-scale application in industry faces large challenges because of its uneven treatment materials, high equipment cost and diversity of carrier gas selection. Limited penetration is also a major obstacle to its applicability, which depends on its half-life and treatment materials. In the case of dense cells, the top cell layer must be decomposed or destroyed, otherwise the cells below the penetration depth cannot be affected[30].

The research on the safety performance evaluation of CP applications is scarce. With the increase of CP treatment time and power, the nitrate and nitrite content in the substrate grows, which has a certain effect on the cell activity[67]. The solution treated by CP has shown selective cytotoxicity in mammalian cell models, which provides some reference for the treatment of cancer cells in medicine[68]. Chen et al.[69] also observed that the efficiency of apoptosis rate was positively correlated with the concentration of ROS and RNS in plasma-activated water generated with helium as the carrier gas. It is worth noting that although CP showed excellent bactericidal and toxicity reduction effects in food industry wastewater treatment, some reactive substances and biologically relevant factors generated in the plasma discharge can also have toxic effects on some ecotoxic biomarkers such as Daphnia magna[70]. Because of the diversity of CP sources and the multiplicity of chemical reactions, the determination of minimum safe doses, exposure times and the simulation of toxicological effects in the food industry are major areas for future research[71].

-

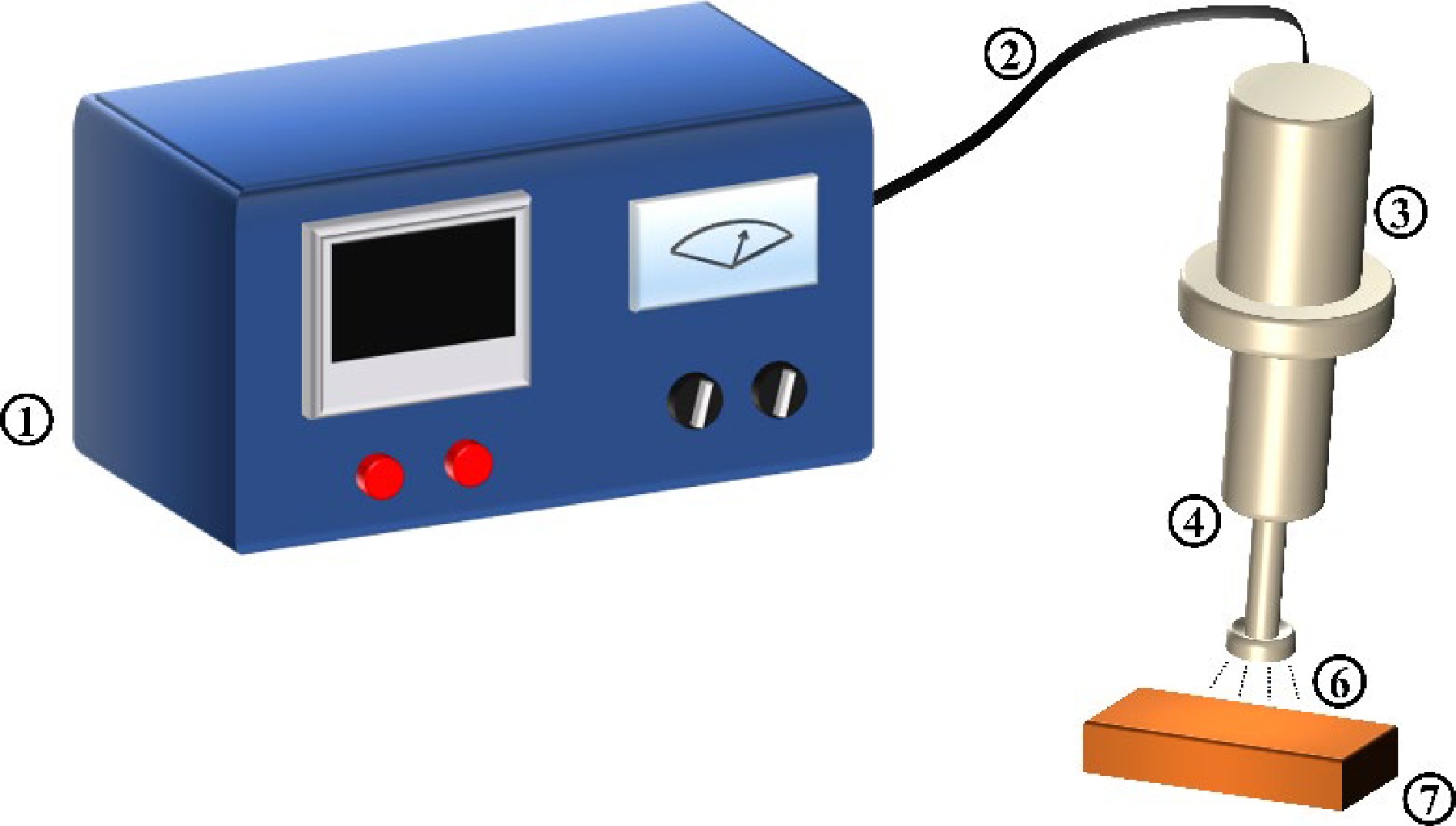

Acoustic wave is a kind of mechanical wave. When their frequencies are higher than the upper limit of human hearing (20 kHz) and cannot be captured by human ears, they are regarded as ultrasound. According to frequency and power, the ultrasound can be classified as high frequency low power (frequency > 100 kHz, intensity < 1 W·cm−2) and low frequency high power (20~100 kHz, 10~1,000 W·cm−2). High-frequency and low-power ultrasound is mainly used for non-destructive purposes, and its weakening or non-cavitation effect will hardly cause physical or chemical changes of the processed materials. It is mainly used to detect the characteristics (composition, structure, physical and chemical state) of food materials in the food industry, and it is also used for production process control, such as detecting foreign matter[72,73]. Low-frequency and high-power ultrasound, also known as power ultrasound, is usually characterized by the generation of fast-moving microbubble streams and bubble collapse, resulting in changes in the physical, chemical and even biochemical properties of food products. Therefore, it is widely used in food cleaning, liquid degassing, cell crushing, biological extraction and microbial inactivation, etc[74]. In recent years, high-power ultrasound was also proven to play an active role in the process of food drying[75]. When it is applied to food drying, it mainly includes two different ways, namely ultrasound pretreatment and ultrasound assisted drying. Generally, ultrasound pretreatment can be divided into two ways, one is to use an ultrasound water bath, and the other is to transmit ultrasound waves to the probe in liquid medium for action[76]. The ultrasound generation system consists of three main components: the generator, the transducer and the emitter. The role of the ultrasound generator is to convert the utility power into a high-frequency alternating current signal that matches the ultrasound transducer, driving the ultrasound transducer to work. And the transducer converts the incoming electrical signal into a mechanical signal (i.e. ultrasound). Finally, the emitter then delivers the converted energy (ultrasound) to the sample being processed, as demonstrated in Fig. 4.

Figure 4.

Acoustic wave generating system. 1. Ultrasound generator, 2. electric energy, 3. ultrasound transducer, 4. emitter, 6. ultrasound, 7. samples.

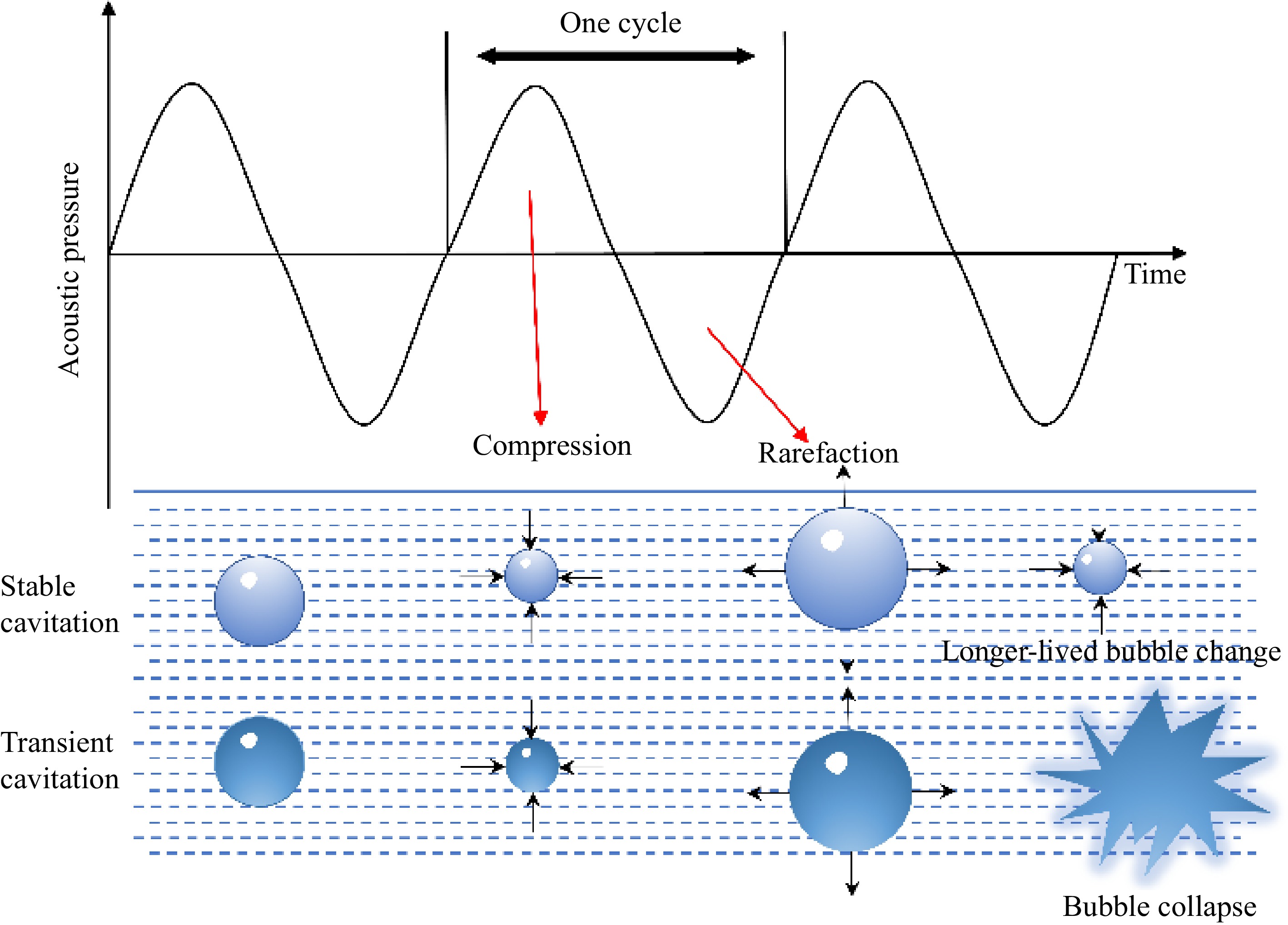

The transducer is the most critical component in ultrasound equipment, and piezoelectric and magnetostrictive transducers are widely used in the market at present. When the transducer works, it converts mechanical energy or electrical energy into a certain form of acoustic wave, and produces compression and thinning in the liquid medium (high and low pressure areas). When the low pressure generated by rarefaction exceeds the critical intermolecular force of liquid medium, microbubbles would be formed. Under the thinning and compression of acoustic waves, microbubbles undergo dynamic changes such as expansion and contraction, and the generation and subsequent dynamic changes of microbubbles are called cavitation effect[77]. The response of tiny bubbles in liquid may be mild or strong under the action of sound field, so they can be divided into two types: steady cavitation and transient cavitation[78]. The former is a longer-lived bubble change, which generally lasts for several acoustic cycles. As the ultrasound power does not reach the threshold (generally 1 W·cm−2), the bubble cannot reach the critical size of collapse or implosion in the process of expansion and compression, and the cavitation effect is more stable. The latter refers to the more intense dynamic changes of microbubbles in an acoustic cycle after the ultrasound power exceeds the threshold, with the process of initial birth, development and subsequent rapid closure and bursting. When the microbubble exceeds a critical size, it rapidly closes and bursts, triggering a collapse or implosion and generating a surge wave. During this period, a large amount of energy is released, which subsequently leads to transient extreme temperature and pressure conditions (up to 5000 K and 1000 atm) at the molecular level, as shown in Fig. 5. At the same time, high shear and turbulence are generated around the cavitating bubble[79]. In this extreme environment, water molecules are broken down into highly reactive radicals (·H and ·OH), which promote certain chemical reactions and modifications of some molecules in the sample, called the chemical effect of ultrasound[80].

On the other hand, the implosion of cavitation bubbles near the solid-liquid interface may lead to micro-jets, which pass through and leave the bubbles and impact the solid surface, thus improving the mass and heat transfer between liquid and solid by destroying their respective diffusion boundary layers[81]. In addition, when ultrasound propagates in the solid-liquid system, it causes turbulence in the solid-liquid interface and destroys the surface of the solid food, thus promoting the acoustic-physical effect, reducing the diffusion boundary layer and accelerating the mass and heat transfer[82]. Once the wave reaches the solid, it produces alternating compression and expansion, resulting in a sponge effect in the solid. This mechanical effect leads to the creation of microscopic channels on the surface of the solid, which largely accelerates the mass transfer or moisture migration during the drying process.

Application of ultrasound

-

For ultrasound pretreatment, the food may lose or gain moisture due to the combined effect of ultrasound pretreatment and the concentration gradient between the food and the liquid medium (distilled water or permeate solution). With the increase of ultrasound parameters (ultrasound time, amplitude and ultrasound power), the moisture loss or moisture increase. At the same time, the microscopic channels generated by the sponge effect and cavitation effect can increase the moisture transfer rate and enhance the mass transfer process, thus accelerating the drying progress. For example, the introduction of ultrasound pretreatment before microwave-hot air drying of Pleurotus eryngii caused the cells to rupture and irregular pores to form on the surface, which further enhanced the heat and mass transfer and facilitated the escape of water vapor during microwave-hot air drying. With the extension of ultrasound treatment time, the drying time and energy consumption were significantly reduced[83]. When ultrasound wave is used in osmotic dehydration of persimmon fruit, with osmotic dehydration (OD), ultrasound-assisted dehydration produces micro-channels, which leads to water loss. Compared with the control group, using ultrasound-assisted osmotic dehydration (30 min ultrasound +OD) before hot air drying reduced the total drying time (osmotic dehydration + hot air drying) by about 135 min, and increased the drying rate from 0.375 kg·H2O/h·m2 to 0.430 kg·H2O/h·m2[84]. Similarly, Azoubel et al.[85] used 56% (w/w) sucrose solution to permeate papaya, and the effective water diffusion coefficient measured by fluidized bed drying was 1.21 × 10−9 m2·s−1, which was lower than that of fresh fruit (2.78 × 10−9 m2·s−1), because the solid phase gain during permeation increased the mass transfer resistance. However, by using a 25 kHz ultrasound bath for 10−30 min assisted osmotic dehydration, the effective water diffusion coefficient can be increased to 2.32 × 10−9 m2·s−1.

Furthermore, ultrasound waves could reduce the water activity, improve product color and reduce nutrient loss. The increase of mass transfer shortens the drying time of the food, and to a certain extent, reduces the contact between the food and air, and inhibit the oxidation of the food. A study showed that the ultrasound treatment of bitter melon followed by hot air drying and radio frequency assisted hot air reduced the drying time by 11.2% and 33.4% respectively. At the same time, the rehydration ability and the total phenol content retention rate of bitter melon increased, and the texture characteristics of balsam pear improved[86]. Xu et al.[87] found that the freeze-drying time of ultrasound-treated strawberry slices shortened by about 15.25%−50.00%, and the quality attributes such as rehydration, hardness, color, flavor, total anthocyanins, total phenols, and antioxidant activity were significantly superior to those of the control and other pretreatment samples. Besides, different frequency modes of ultrasound pretreatment had significant effects on the drying process and quality attributes of strawberry slices, and dual-frequency ultrasound shortened the drying time more than single-frequency ones.

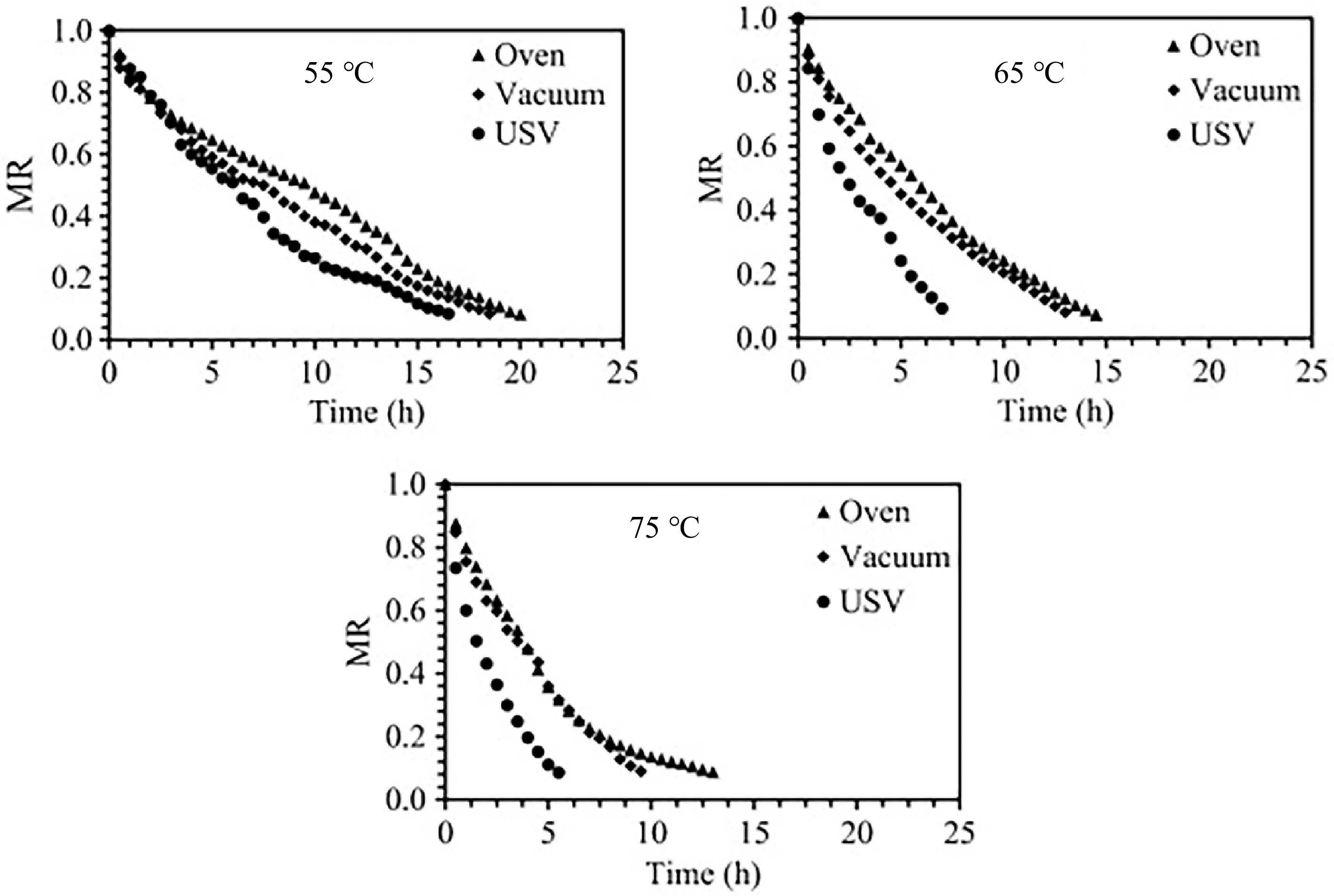

The severe hydrodynamic force caused by bubble bursting or instantaneous cavitation can cause serious damage in biological media, thus destroying the fiber structure of muscle, such as the rupture of lysosomes, the destruction of myofibrillar protein and the increase of proteolysis, which led to the tenderizing of meat[88]. Various ultrasound powers have different effects on meat tenderization, mainly involving denaturation of cytoskeletal proteins responsible for maintaining muscle structure, thus changing the structure of muscle fibers and reducing shear forces[89]. It was also shown in a myriad of studies that the compression and thinning effects of ultrasound modified cell membranes and formed microscopic channels in meat cells, which facilitated mass transfer. For example, the application of ultrasound during the brining/curing of meat increased the mass transfer rate, mainly due to the various physical and chemical effects that disrupted the continuity of the cell membrane[90]. Theoretically, the creation of microscopic channels and the collapse of the muscle fiber structure are extremely beneficial for the moisture transport during drying. However, the application of ultrasound to meat drying mainly relies on the auxiliary form and is less surveyed. Table 2 summarized the development of ultrasound-assisted application to chicken, beef and fish meat drying in recent years. The drying profiles of chicken meat using ultrasound-assisted vacuum drying (USV), vacuum drying (Vacuum) and oven drying (Oven) at 55 °C, 65 °C and 75 °C were depicted as in Fig. 6. The moisture ratio (MR) in ultrasonically treated chicken meat decreased exponentially with increasing time. The combination of ultrasound and vacuum showed higher water loss rate and lower drying time compared to oven and vacuum drying[91].

Table 2. Progress of ultrasonic assisted drying applied to meat and aquatic products.

Material Device Drying method Main results Reference Beef, chicken Ultrasonic water bath Ultrasound-assisted vacuum drying MR in ultrasonically treated chicken meat decreased exponentially with increasing time. The combination of ultrasound and vacuum showed higher water loss rate and lower drying time compared to oven and vacuum drying. [91] Chicken breast Probe Combined supercritical CO2-ultrasonic drying The synergistic effect of supercritical CO2 and ultrasound promotes drying kinetics. High-power ultrasound enhanced water extraction, greatly reduced drying time, and resulted in lower water activity and higher porosity of the final samples. [92] Minced meat Ultrasonic water bath Ultrasound-assisted vacuum drying Compared to vacuum drying, ultrasound-assisted vacuum drying showed lower drying times, higher rehydration values, higher porosity, more open structure and lower peroxide values at all temperatures. [93] Pork liver Airborne ultrasound Ultrasound-assisted hot air drying The application of ultrasound improves the drying rate and reduces the drying time by 40% at 30 °C, but power ultrasound has less effect on the drying rate at high temperatures (60 °C and 70 °C). [94] Salted cod Airborne ultrasound Ultrasound-assisted hot air drying Application of power ultrasound at low temperatures increased the drying rate, reducing the drying time by 35−50% on average and increasing the lightness (L*). Microstructural analysis showed that the application of ultrasound during drying caused changes in the cod fibers, resulting in higher rehydration capacity and softer samples. [95] Clipfish Airborne ultrasound Ultrasound-assisted convective drying The drying time at 20 °C can be reduced by 43% at an ultrasonic intensity of 25 W·kg−1. The energy consumption for ultrasonic drying increase multiple times despite its faster dehydration. In addition, the water distribution in batch drying is uneven and the ultrasonic energy in the system is excessive. [96]

Figure 6.

Drying curves of chicken breast meat dried with different techniques[91].

Unfortunately, few arguments were available for the significant effect of ultrasound pretreatment on the promotion of meat drying rate. Ultrasound pretreatment at 25, 33 and 45 kHz for 30 min prior to curing of beef was reported to significantly promote the absorption of salt water, which may be due to the combined effect of cavitation and concentration gradient, but the improvement in subsequent drying rate was not obvious[97]. In fact, the effectiveness of ultrasound pretreatment for drying depends largely on the food matrix, ultrasound processing parameters and drying temperature. For one thing, compared to agricultural products, thicker tissues and dense muscle fiber structures may require higher ultrasound power and duration to form micro-channels or destroy muscle fiber structures, thus promoting mass transfer. For another thing, in the process of meat drying, higher drying temperature and more intense drying methods are often needed than those of agricultural products, so the improvement of structure by ultrasound pretreatment is prone to be ignored.

Limitations of ultrasound

-

The effect of ultrasound treatment is largely related to the type of food and the drying method. After ultrasound pretreatment of some food matrices, the drying time was significantly reduced, while in some cases, the drying time was only slightly reduced. For example, Horuz et al.[98] applied an ultrasound water bath with frequency of 25 kHz for 0−40 min and microwave with frequency of 120−180 W to dry tomato slices. It was found that when the microwave power was 120 W, the drying time of ultrasound pretreatment for 40 min was only shortened by 7.38% compared with that without ultrasonic pretreatment, which indicated ultrasound pretreatment has little effect on drying rate, while microwave power has a great effect on drying rate. Similarly, Rodríguez et al.[99] adopted ultrasound-assisted hot air drying of apples. The drying time reduced about 37% (30 °C and 18 kW·m−3) and 53.8% (30 °C and 30 kW·m−3) compared to the results of hot air drying alone. However, when the temperature was increased to 70 °C, the drying time was shortened by 8.7% and 17.4% for ultrasound treatment of 18 and 30 kW·m−3, respectively, resulting in a reduced effect of ultrasound on the apples. In other words, the increase in temperature causes the improving in ultrasound drying rate to become less noticeable. Therefore, the selection of different drying methods and drying conditions may affect or even offset the effect of ultrasound pretreatment.

In addition, ultrasound waves propagating in the medium cause the mass to vibrate. Due to the existence of internal friction in the propagating medium, part of the acoustic energy is absorbed by the medium and transformed into heat energy[100]. Although ultrasound is defined as a non-thermal treatment, strong high-frequency oscillations, friction and heat energy are generated inside the material as it is applied for a long time, especially in the process of contact ultrasound[101]. To prevent this undesirable phenomenon, some studies attempted to treat samples using intermittent ultrasound[101,102].

The main parameters characterizing the acoustic waves or sources are: frequency, wavelength, amplitude, propagation velocity, phase shift, beam, power consumption (net power), intensity, etc. Although these parameters are of key importance when considering different ultrasound systems, their detailed descriptions are rarely mentioned in the literature. Moreover, even though authors usually report the frequency of the generated ultrasound waves (e.g., 20 or 25 kHz), the wave amplitude is often omitted. In addition, the acoustic energy delivered to the material is often incorrectly identified as the energy consumption of the ultrasound system (generator). Only in a few studies have authors considered the power of the incident wave and defined it properly as: intensity (kW·m−2), sound power (W) or sound pressure level (dB). For these reasons, comparative analysis between ultrasound treatments reported in different studies is almost impossible[100].

-

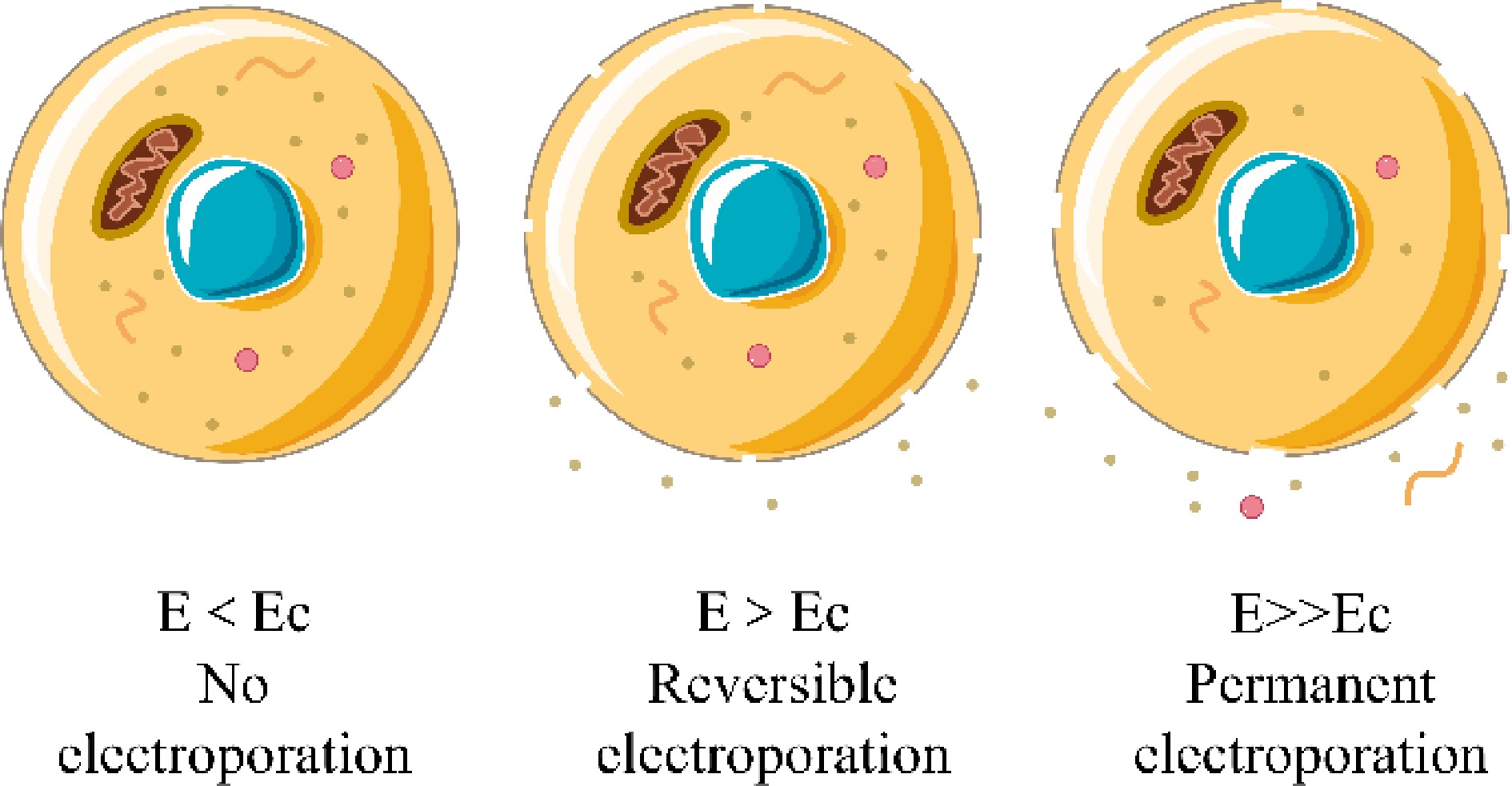

Pulsed electric field (PEF) is a new technology that utilizes short pulses of microsecond voltage (<80 kV) to create a potential difference in the material between two electrodes, producing an electroporation effect to improve cell permeability[103]. The electroporation hypothesis is based on the polarizing effect of high-voltage pulsed electric fields on the cell membrane framework structure[104]. Under normal conditions in biological cells, due to the uneven distribution and localized aggregation of proteins and lipids in the cell membrane, the opposite polar charges accumulate on both sides of the membrane, inducing a vertical transmembrane potential of about 10 mV[105]. The conductivity of the intact cell membrane is several orders of magnitude lower than that of the extracellular medium and cytoplasm. When biological cells are exposed to the external electric field (E), the charging process at the membrane interface causes the charge to move in the direction of the electric field, resulting in an additional potential (an increase in the transmembrane potential)[106]. Each cell has a different critical electric field (Ec), which depends largely on the size and shape of the cell as well as the electrical conductivity of the cytosol. As shown in Fig. 7, when the external electric field is less than the critical electric field (E < Ec), no electroporation occurs. When the external electric field is the same as or slightly higher than the critical electric field (E > Ec), the reversible electroporation occurs. In the process of reversible electroporation, the cell membrane appears temporary electroporation under the action of electric field, and regains its original structure when the electric field is removed. Only when the intensity of the external electric field is much higher than the critical electric field (E >> Ec), permanent electroporation of the membrane occurs, leading to cell death and release of cell contents[107]. Factors such as electric field strength, pulse shape, number and duration, as well as temperature may affect the effect of PEF.

Currently, pulsed electric field has been proven to have promising effects in the fields of inactivation of microorganisms[108], assisted fermentation[109], assisted extraction[110,111], assisted freeze thawing[112,113] and inhibition of enzyme activity[114]. Its main advantages are high efficiency, low energy consumption, few by-products, no pollution to the environment, and the application of short electric pulses at high voltage keeps the control of thermal effect at a low level, which fully protects the flavor characteristics of materials. Therefore, this method can be applied to almost any temperature-sensitive food matrix.

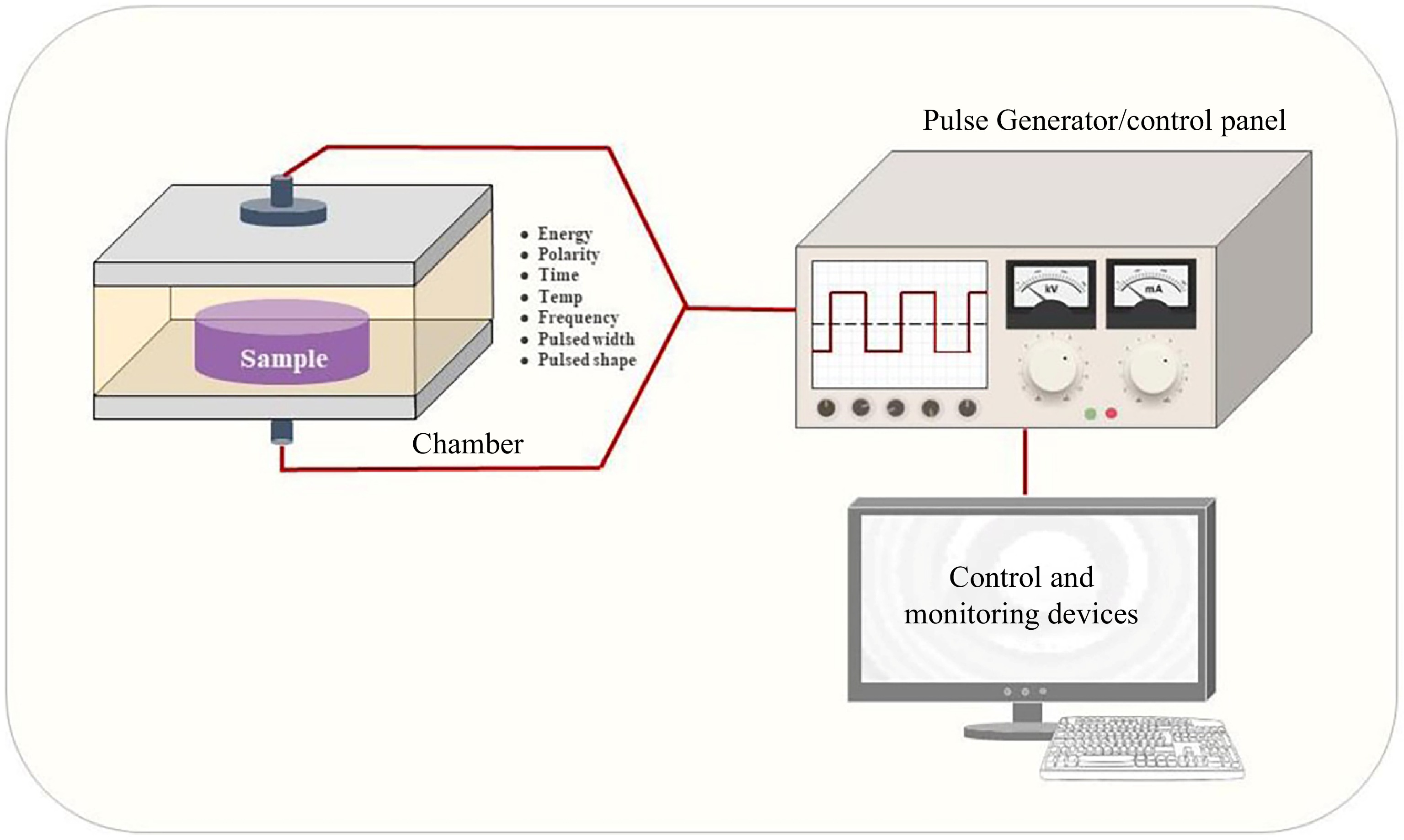

A PEF processing system mainly includes three parts (Fig. 8): (1) Pulse generators that provide pulses of a given voltage, shape and duration; (2) Treatment chamber with multiple electrodes, and the electrode gap is filled with the liquid or water substance to be treated; (3) Control system for setting and monitoring conditions. The pulse generator is the most critical part of the PEF system and consists of various electrical components such as capacitors, inductors, resistors, transformers and power switches. And it plays an important role in PEF processing, including storage of electrical energy, generation of high-energy pulses and transmission of various waveform pulses[115]. The treatment chamber is equipped with at least two electrodes (a discharge electrode and a grounding electrode), and is divided into an intermittent treatment chamber and a continuous treatment chamber according to the state of the processed sample (solid, semi-solid, liquid and semi-liquid). The control system is responsible for monitoring and controlling various process parameters, such as electric field strength, pulse number, pulse width, product flow rate, etc. Optimizing different PEF equipment settings and process parameters can ensure the treatment process achieves desirable results.

Figure 8.

Schematic diagram of the primary components of pulsed electric field (PEF) food processing systems[116].

Application of PEF

-

Polar molecules in food products can produce dipole vibrations, reorientation, translation and rotation when subjected to external electric fields, leading to different degrees of modification. Some enzymes that control oxidation and browning in food, such as PPO, lipid oxidase (LOX), and POD, are mostly composed of amphiphilic biomolecules (proteins) and have dipole moments and net charges that are sensitive to applied electric fields[117]. Pretreatment of inhibition or inactivation of these enzymes was proven to effectively control the degradation of the sensory quality of the material due to the enzymatic reaction during drying. On the one hand, under the action of the applied electric field, the polar groups of proteins absorb the electric field energy and then generate free radicals or cause the aggregation and unfolding of proteins. Since free radicals may disrupt various interactions between protein molecules, including van der Waals forces, electrostatic interactions, hydrophobic interactions, hydrogen bonds, disulfide bonds and ionic bonds, the structure and functional properties of protein are changed to varying degrees[118]. The results of circular dichroism analysis showed that PEF treatment caused conformational changes in the secondary structures of PPO and LOX, resulting in the loss of the α-helix and an increase in the β-fold content. Meanwhile, the fluorescence intensity of LOX increased with the rise of applied electric field intensity, which proved that the local tertiary structure of LOX protein changed[119]. On the other hand, a certain intensity of PEF treatment may generate heat that leads to denaturation and aggregation of heat-sensitive proteins, resulting in enzyme inactivation. In contrast, low-intensity PEF treatment has relatively little effect on protein structure and function because the thermal effect generated by low-intensity arc is not sufficient to bring the protein to a denatured state. For example, Huang et al.[120] found that PEF treatment of 0.65−1.25 kV·cm−1 for 30−60 s had no effect on PPO activity in apricots, but significantly reduced POD activity (63.4%−74.4%). Also, the PEF treatment retained more β-carotene in apricots compared to the untreated samples, and less browning was observed after hot air drying. On the contrary, in a study on the enzyme activity of apple juice, different electric field intensities (0−35 kV·cm−1) and pulse rise times (PRT) of 2 μs and 0.2 μs produced different degrees of effects on the enzyme activity. Especially at 35 kV·cm−1 and 2 μs-PRT, both enzymes were almost completely inactivated. The residual activities (RA) of PPO and POD decreased with increasing electric field intensity, indicating that the higher the electric field intensity of the PEF treatment, the greater the decrease in the residual activities of PPO and POD. Moreover, the inactivation of enzymes treated with 2 μS-PRT was better than those treated with 0.2 μS-PRT at the same electric field intensity, which may be due to the higher energy density of the pulsed electric field input of 2 μS-PRT, which increased the temperature of the samples by 9.2−20.7 °C, resulting in the thermal inactivation of POD and PPO[121].

Table 3 listed the main advances in PEF pretreatment technology applied to dry agricultural products. An extremely short high voltage pulse is applied to the food placed between the electrodes, which leads to electroporation, including the formation of new membrane pores and the growth of existing membrane pores. Due to the altered cellular structure of the plant material, electroporation of cell membranes facilitates drying and other processes based on mass and heat transfer to some extent[122]. Pretreatment of apples with PEF prior to freeze drying (FD) resulted in 17.73% and 24.74% reduction in drying time and specific energy consumption, respectively. In addition, the apples had higher rehydration rate (65.22%), lower shrinkage, more porous and irregular structure after pretreament[123]. The results of Bogusz et al.[124] indicated that the PEF pretreatment (1.07 kV/cm, 5 or 20 kJ/kg) promoted the water evaporation kinetics of insect biomass obviously, especially in the range of the moisture ratio (MR) from 1.0 to 0.2, and the electroporation of insect cell membrane led to the enhancement of mass transfer during drying. In addition, there is less soluble solids lost, better color retention and reduced microbial load of fresh larvae by 0.5–1.0 log cycle in the PEF-treated samples.

Table 3. Major advances in PEF pretreatment to dry agricultural products.

Material Conditions Drying method Main results Reference Apples tissue 1−2 kV·cm−1, 90 μs,

10−60 pulsesFreeze drying PEF treatment prior to FD saved the energy approximately 24.74% and greatly improved the rehydration ratio of apple tissue. [123] Black soldier fly, yellow mealworm 30 kV, 40 μs, 2 Hz,

5/20 kJ·kg−1Infrared drying PEF treatment promoted the evaporation of water of insect biomass obviously due to the acceleration of mass transfer during drying and maintained the soluble solids content as well as fresh color of products. [124] Apples 1000 V·cm−1, 120 μs,

30 pulsesVacuum freeze-drying The energy consumption was reduced by 20.46% and the drying time was shortened by 22.50%. [125] Carrots 5 kV·cm−1, 10 pulses Microwave-assisted drying PEF treatment reduces drying time by 50%, retains 93.7% of carotenoids, enhances rehydration, increases porosity, and maintains color. [126] Parsnip 0.9 kV·cm−1, 1000 pulses Convective drying The drying time decreased by 5% and 28%, and the effective diffusion of water increased by 38%, which had no significant effect on the mechanical properties. [127] Mango 30 kV, 40 μs, 2 Hz, 1.07 kV·cm−1, 1 or 3 kJ/kg Convective drying and vacuum drying The retention of phenolic compounds in the PEF pretreated materials was 70% higher than that of the untreated ones, but the antioxidant capacity of dried mangoes decreased after high energy PEF treatment. [128] Red pepper 2.5 kV·cm−1, 100 Hz, 4 s Hot air drying The drying time was reduced by 34.7%, and the color and quality of dried red pepper improved. [129] Previous studies demonstrated that PEF not only optimized the structure and properties of meat, but also improved meat quality, accelerated mass transfer during drying, accelerated the uptake of inorganic salts during curing, and enhanced water binding properties through diffusion of water-bound molecules[130]. Most studies on the effects of PEF focused on its application in accelerating meat tenderization in meat products, where electroporation of muscle cells would promote the release of calcium ions necessary for protease activation, thereby accelerating the protein hydrolysis process and tenderizing/ripening the meat[131]. However, few studies evaluated the potential of PEF to accelerate mass transfer processes (drying and curing) in meat. Zhang et al.[132] observed that the diffusion coefficients of NaCl and water were increased by 51.8% and 69.0%, respectively, and the halogenation time was reduced by nearly 33% after treatment of beef at 2.0 kV/ cm, 125 pulses, and 12.50 kJ/kg due to the widening of the gap between muscle bundles and the enhancement of their membrane permeability.

The mechanism of PEF treatment to promote meat drying mainly includes two aspects: (1) Electroporation effect caused by pre-drying dehydration shortens the drying time and reduces the energy required for evaporation. (2) The increase of effective moisture diffusion coefficient in the drying process caused by the increase of porosity, which accelerates the mass transfer[133]. When PEF treatment was applied to chicken breast with 1000 V, 120 pulses, 50 μs pulse width and 1 Hz frequency, the effective diffusion coefficient of moisture increased by 13%−24%, and the convective air drying time was reduced by 6.4%−15.3%[134]. In addition, PEF can also be used as a pretreatment for dewatering to improve moisture removal without substantial impact on solids gain. No phase change is involved in the dewatering process, so PEF combined with mechanical dewatering can save the energy required for the convective drying process. For example, Ghosh et al.[135] used Taguchi's robust design to optimize the process parameters and found that the number of pulses and voltage play a key role in the dehydration of chicken breast. The optimal parameters revealed that the PEF treatment with voltage of 75 V, pulse length of 7 ms, pulse number of 300, frequency of 2 Hz, electric field intensity of 11.4 V·mm−1 and continuous mechanical load of 125.44 kPa had the most obvious dehydration effect. Most importantly, the increase in porosity of chicken meat caused by the electroporation effect resulted in an effective diffusion coefficient of water of 1.88 × 10−9 m2·s−1 during hot air drying at 60 °C, which was significantly higher than that of 3.40 × 10−10 m2·s−1 in the control group, with an overall energy saving of 933.18 ± 22 J·g−1. It should be noted that the results obtained were not conclusive in some cases and in some applications, probably because the effect of PEF on meat is difficult to capture. In addition to the treatment parameters (electric field strength, pulse width, specific energy or treatment time), the effect of electroporation depends on many factors inherent to the substrate, such as the type of animal, the cut of the meat, the orientation of the fibers, the previously applied refrigeration or freezing treatment, etc[136].

Limitations of PEF

-

Studies suggested that the promotion effect of PEF on drying does not increase continuously with the growth of electric field strength as well as the number of pulses[137,138]. In fact, the electroporation effect has a saturation behavior. Electroporation oversaturation may lead to collapse of plant tissues during drying and limit the progress of drying due to greater disintegration of cell membranes[139]. Therefore, for each raw material and equipment, optimal parameters for PEF treatment exist. Wiktor et al.[140] found that the drying time of carrots treated with PEF reduced by 8.2% and the effective diffusion coefficient of water increased by 16.7% at an electric field intensity of 5 kV/cm , pulse number of 10 and specific energy input of 8 kJ·kg−1 compared to the control group. In contrast, the drying time of the samples treated with higher pulse number at the same electric field intensity (5 kV·cm−1; pulse number of 100, specific energy input of 80 kJ·kg−1) was not significantly shortened.

Although PEF treatment is a non-thermal processing technique, the process of high-intensity PEF treatment is often accompanied by an increase in temperature due to Ohmic heating or weak joule effect, resulting in denaturation and inactivation of heat-sensitive compounds such as proteins, polyphenols and pigments in the food matrix. According to different process parameters and treatment conditions, the side effects of PEF, such as a certain temperature increase or electrochemical reactions, must be taken into account in order to maintain food quality. In summary, the adjustment of the treatment parameters or the optimization of the equipment structure (e.g. the design of the treatment chamber) may have a positive effect on the reduction of side effects.

Besides, although the PEF pretreatment technology was highly evaluated in many studies, the application of PEF is still in the laboratory stage. One of the reasons is the high initial investment cost of pulsed electric field equipment (high production costs), and the development of reliable, industrial-scale and high-intensity pulsed electric field power generation equipment (scaling-up process) continues to face many problems. For example, high frequency processing inevitably aggravates electrochemical reactions at the electrode/media interface, which indicates a challenge in avoiding electrode corrosion and migration of electrode materials into food systems, and the common stainless steel electrodes may be replaced by other materials in the future[141]. Another limitation of PEF is the inhomogeneity of processing in complex food matrices, and all studies on its meat aspects today are conducted on fat-free and bone-free meat samples. In contrast, in industry, cutting the bone with different fat content provides a matrix with uneven tissue density, and the conductivity of fat and bone is lower than that of other parts, which leads to various effects of PEF on different parts of the product[142].

-

In order to improve the nutrient retention and edible quality of food, and shorten the drying time, novel non-thermal pretreatments are often applied instead of conventional pretreatments before drying. Surface corrosion, electroporation, cavitation effect and other effects make the material surface denaturation, accelerating the mass transfer rate and reducing energy consumption. However, the morphology, organization and structure of different food raw materials or different varieties of the same raw material are quite different, and only relying on one treatment condition cannot produce positive effects on all products. In order to improve the overall drying process, individual studies are needed between different raw materials or varieties to establish their own suitable drying conditions and parameters.

In addition, the application of non-thermal pretreatment technology still has some urgent problems to be solved. Although defined as non-thermal pretreatment, the process is often accompanied by a local increase in temperature of the treated material, resulting in some changes in color and physicochemical properties. For example, the rupture of microbubbles generated by ultrasonic cavitation causes thermal effects of extreme localized high temperature and pressure in the material (5,000 K and 1,000 atm), which produces undesired color changes and loss of heat-sensitive substances during pretreatment. Therefore, efforts should be made to reduce the temperature increase by intermittent treatment or by incorporating a cooling system.

Techniques such as PEF and US are usually performed by immersing the raw material in a special liquid matrix. Nutrient leaching and various browning reactions are more likely to occur due to the formation of free radicals and leakage of biomolecules caused by electroporation or cavitation effects, especially at higher treatment parameters or longer treatment times. Therefore, the development of devices that directly contact and act on materials instead of relying on liquid media is of great significance to the optimization of drying processes.

Last but not least, new technologies combining non-thermal pretreatment with combined-drying were also investigated, while some studies pointed out that the combined treatment techniques of two or more pretreatment methods, such as PEF and US, can further improve the drying characteristics of fruits and vegetables. Since PEF pretreatment affects the structure of the product, while the treatment effect of US depends on the internal structure of the product, the combination of both can have a synergistic effect. In conclusion, the study of the interaction or synergy of several pretreatment or drying methods may lead to a greater breakthrough in further improving drying efficiency and product quality.

This research was supported by Key Scientific and Technological Research Projects of Xinjiang Production and Construction Corps (2022AB001), the National Natural Science Foundation of China (No. 32272252), and the China Agriculture Research System (CARS-41) funded by the Chinese Ministry of Agriculture.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Gao J, Chen L, Zeng X, Sun X, Bai Y, et al. 2023. Novel drying pretreatment technologies and their applications in the food industry. Food Materials Research 3:14 doi: 10.48130/FMR-2023-0014

Novel drying pretreatment technologies and their applications in the food industry

- Received: 28 February 2023

- Accepted: 02 June 2023

- Published online: 28 July 2023

Abstract: Fresh foods especially fruits, vegetables, meat, poultry and aquatic products are highly perishable due to high moisture content and rich nutrient matrix, which leads to microbial growth, enzymatic and oxidative reactions. As a common food processing method, drying inhibits spoilage microorganisms and oxidation reactions as well as retaining nutrients by reducing the moisture content and water activity in food, thus extending product storage life. Pretreatment is a key step for the drying operation. Compared to traditional pretreated and untreated samples, the development and application of new non-thermal pretreatment technologies can not only improve moisture distribution and reduce energy consumption, but also further improve the functional and nutritional attributes of dried products. In the present study, some novel non-thermal pretreatment technologies including cold plasma, ultrasound and pulsed electric field were reviewed. Their detailed working principles and equipment, positive effects on agricultural products and meat products, as well as some possible pros and cons for application are also presented to provide some reference for the development and application of these pretreatment technologies.

-

Key words:

- Food processing /

- Non-thermal pretreatment /

- Principle /

- Equipment /

- Applications