-

With an annual output value of over 34 and 23 billion Euros in 2018, vegetables and fruits are, respectively, key European Union (EU) agricultural products[1]. Fruits and vegetables accounted for approximately 14% of the total value of the EU's agricultural production in 2018[1]. Indeed, it was estimated that 1.9% of all utilised agricultural land in the EU (3.4 million hectares) and 1.2% of all EU arable land (2.2 million hectares) in 2017, was dedicated to growing fruit and vegetables, respectively[2]. The Italian agri-food sector continues to grow. The value of the food and beverage commercialisation in Italy has reached 538 billion Euros, equal to the 25% of the gross domestic product[3]. In particular, the Agriculture 4.0 movement is now riding the wave of change towards technological improvements regarding precision agriculture[4], traceability and, more generally, data analysis performed through software that find applications in the different phases of cultivation, sowing, harvesting and food processing.

In Italy, the fruits and vegetables sector represents a business of 13 billion Euros. Considering the 2020 reports of the agri-food observatory, there are about 330,000 fruit and vegetable companies in Italy, which occupy the 8% of the utilized agricultural area. The largest area of this share is occupied by the fruit sector, which amounts to 377,470 hectares[5]. In particular, Italy produces 34% of EU tomatoes and 31% and 32% of EU pears and peaches production, respectively[1]. It is also the world leading artichoke producer harvesting around 500,000 tons per year.

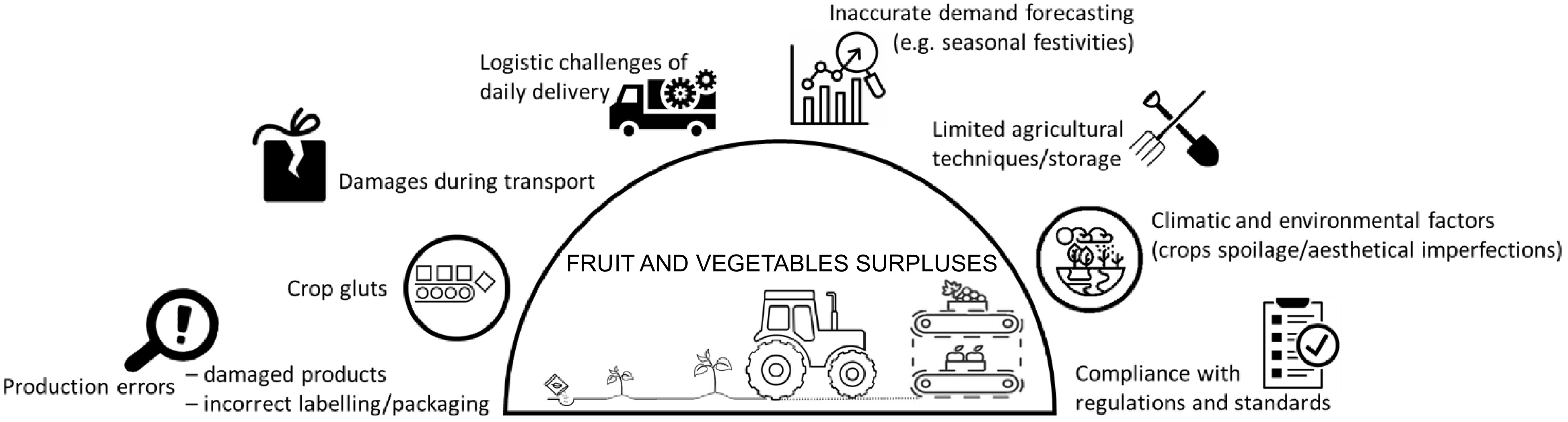

One of the main difficulties of the fruits and vegetables production sector is that of food surpluses (Fig. 1). Such food surpluses may be caused by limited agricultural techniques, adverse climatic factors and errors in forecasting market demand. On the other hand, at the transformation and distribution level of the supply chain, there might be losses due to processing and packaging errors, damages during transport and storage fallacies. Finally, waste generation can be found at the level of retail and consumption, due to labelling and storage errors and surpluses on purchase and conservation.

It must be highlighted that fruits and vegetables are highly perishable and their marketability as fresh products is severely limited by high quality standards. Such standards relate to weight, size, shape, colour and other aesthetic requirements. Supermarkets often refuse to buy products with the wrong shape or size, therefore farmers are forced to further overplant. As a consequence, all products not complying with those strict requisites are considered surpluses which, if badly managed, lead to the generation of losses or waste. According to an FAO report, in Europe, in the fruit and vegetable commodity group, a total of 45% waste is generated throughout the entire supply chain[6] with respect to the total production. A more recent publication still confirms that such fresh products are the main contributors to losses[7]. In particular, losses in agricultural production (20%) dominate mostly due to post-harvest fruits and vegetables grading as a result of quality standards set by retailers[6]. In Italy, the amount of fruits and vegetables surpluses during the production stage is around 2.2 million tonnes per year[8] representing the 36% of the total food surplus throughout the entire Italian food supply chain.

-

Food surpluses, are defined as food suitable for consumption but which are not sold or consumed for various reasons. When not valorised, negative implications connected to the consequent generation of losses add a burden to social, economic and environmental costs. In Italy, due to agri-food surpluses (5.6 million tons), 12.6 billion Euros are lost per year and 13 million tons of CO2-equivalent are emitted into the atmosphere[9,10]. With a focus on fruits and vegetables surpluses generated during the primary production phase, the best option for managing these surpluses is prevention, i.e. identifying the critical points of the cultivation stage and taking action on them. However, once surpluses are generated, they should be destined for reuse (i.a., donation) and recycling (food processing) (Table 1).

Table 1. Actions to apply the 3Rs – Reduce, Reuse, Recycle – to fruits and vegetables surpluses.

Actions Challenges Reduce Collaboration/information exchange among all supply-chain stakeholders • Dearth of data mining (more sensors, energy counters and flow meters shall be installed for data-collection), elaboration and processing is an issue.

• There is the tendency of preferring the cheapest solutions rather than the most sustainable ones.Audit – detailed measuring of food productions Genetically engineered crops Improved forecasting process (consumers' demand, market trends) Thermal preservation (refrigeration, cold chains) and improved cold chain logistics Smart packaging, labelling and storage technologies Comprehensive analysis of pathogens virulence mechanisms to limit acidic fungi infections Simpler production processes Digital agriculture (Agriculture 4.0) for optimal real-time farm management Reuse Governmental awareness campaigns • Large-scale distributers foresee key specifications for food safety, that lack in farmers markets as well as during gleaning activities.

• It is necessary to resume solidarity approaches between farm owners and volunteers working for charities.

• Food donations are more common in the food retail industry than in restaurants.NGO programs Authenticity and sustainability food positioning Social media activities (e.g. food sharing apps) Farmers markets promotion Field gleaning Donations Recycle Food processing • Maintaining microbacterial and sensorial quality especially for minimally processed fruits and vegetables is the main challenge.

• Hidden risks besides each possible processing operation should be appraised.Shelf-life extension in derived products Study of food markets trends and consumers preferences Flexibility to foresee and allow creative surpluses repurposing Simulation-based approaches in food processing Animal feed Edible insects biorefinery – nutrients circularity Extraction of bioactive compounds Biomass-to-energy Reduce

-

The main causes related to the production of fruits and vegetables surpluses are the following:

(1) Limits in agricultural techniques and infrastructure for transport and storage,

(2) Climatic and environmental factors (e.g. diseases and infestations),

(3) Production surpluses,

(4) Compliance with regulations and standards.

While in developing countries, the losses are mainly dictated by inefficient agriculture, where technical, financial, structural and managerial skills are limited, in industrialized countries, the adoption of adequate soil preparation techniques, seeds selection, proper sowing time, abundance of water, application of fertilizers and pesticides allow producers to contain losses caused by external factors. However, non-forecasted atmospheric agents may cause significant losses in the field if rapid intervention plans are not available. When supply exceeds the demand or in the case of products affected by hail or with the incorrect size, farmers may prefer to leave them in fields rather than wasting money for their harvesting which would not produce a profit[11]. Fruits and vegetables edibility is not compromised and the main concern becomes the waste of resources used for their production.

The use of genetic engineering can help developing more productive and more resistant plant foods. This technology is commonly used to introduce desirable attributes such as improved colour, aroma, flavour, and taste into different fruits and vegetables products[12] while also increasing their resistance to pests and pathogens.

Nonetheless, a collaborative approach among the various stakeholders operating along the entire food supply chain is the key for reducing food losses and waste and for managing surpluses[8]. A complete information flow would allow framing a system vision where it would be easier designing specific processes and methodologies with an organizational focus dedicated to the reduction of food surpluses.

Besides, active information exchange, reduction strategies are also based on the following actions:

(1) Correctly quanitifying food surpluses: this can be achieved through the monitoring of the cultivation and the engagement of specific audits that must be able to highlight the presence of potential 'hot spots'. Responsibilities must be assigned to the farm owners and co-workers and alert systems must be developed to activate specific intervention plans in advance.

(2) Improving the forecasting process: with a collaborative approach along the entire supply chain[13], the estimation of the impact on the consumers' demand related to the launch of new products and promotional campaigns must be strengthened.

(3) Upgrading fruits and vegetables packaging: packaging should be designed to provide adequate protection during food transport, storage and handling, to maximize the shelf-life of the product and to guarantee the easiest end-of-life management. Furthermore, intelligent food packaging further develops the functions of traditional packages by introducing the capability of continuously tracking[14] and monitoring food quality[15]. Radio frequency identification (RFID) tags, for example, are a type of tracking device that, through the use of radio waves, allows tracing and identifcation of the packaged produce. Unlike traditional barcodes, RFID tags do not require line of sight, meaning that the product does not have to face the reader to transmit data[16,17]. Modified atmosphere packaging (MAP) is another hot topic of research. Microporous MAP can significantly improve gas exchange through the packaging film[18]. The combination of MAP with essential oils[19] and aloe vara gel[20] gave positive outcomes as well as the addition of an adsorbent (e.g. silica gel) that can considerably diminish the accumulation of moisture inside the packaging bags[21]. New sustainable solutions on the market then regard edible food packaging[22].

(4) Simplifying the production process: for certain companies it might be necessary to reduce the range of cultivated products, attention must be paid to the introduction of new products which should not cause surpluses and losses and the respect of the sell-by dates of fresh products must be met thanks to a well-defined logistic.

Decay due to fungal infection is a major cause of postharvest losses in fruits; emerging evidence suggests that organic acids secreted by acidic fungi are important virulence factors[23]. Therefore, a clear understanding of pathogens virulence mechanisms would help designing new technical strategies to prevent postharvest diseases.

Integrating Industry 4.0 technologies into agriculture is key for the development of future farming. In this context, sustainable and intelligent industrial agriculture, Agriculture 4.0, would be achieved through real-time variable fine-grained collection, processing, and analysing of spatial-temporal data (including the use of sensors and micro-controllers for prediction of weather changes) allowing a real-time farm management, a high degree of automation, and data-driven intelligent decision making fit to improve productivity, soil fertility, agro-food supply chain efficiency, food safety, and the use of natural resources[24,25].

To reduce food surpluses and losses while enhancing food safety and quality, attention must be paid to food traceability and food authentication. The European Union has implemented a specific legislation (EU Regulation 178/2002; EU Regulation 1151/2012; Council Regulation, EEC No 2081/92) for monitoring food products protecting each country's culture, history and local economy[26]. The possibility of accessing specific information about a food product at each step of the supply chain has become fundamental for having a unique identification of products, logistic units and locations, for data communication, and for the recording of product/process properties[27]. At the same time, a boosted traceability improves the supply chain performance while reducing food waste. Food traceability and authentication can be performed via nuclear magnetic resonances (NMR), infrared spectroscopy (IR), isotopic techniques, DNA-based methods (e.g. DNA metabarcoding; isothermal amplification-based methods), mass spectrometry (MS), and chromatographic (GC-LC)[26,28].

Agriculture 4.0 and digital innovation in Italy

-

Agriculture 4.0 and mechatronics are the future of Italy's primary sector. Data analytic systems, processing platforms and the Internet of Things are applied in the cultivation phases, sowing and harvesting of fruits and vegetables, wine and cereals. Technological solutions for the agricultural sector in Italy are in constant growth but only 3%−4% of the agricultural area is cultivated with 4.0 tools, a sign that the market has yet to express a large part of its potential[29].

The Italian Agriculture 4.0 market is driven by manufacturers of agricultural and auxiliary machinery, responsible for the 73% of turnover, followed by suppliers of IT solutions and advanced technologies (especially the Internet of Things)[29]. The highest investments are related to solutions for the monitoring and control of agricultural vehicles and equipment (36% of the market) and related equipment (30%), followed by management software (15%), systems for remote monitoring of crops and land (8%), decision support systems (5%), crop and land mapping (4%), robots for field activities (2%).

The application of blockchain is also expected to bring benefits and sustainable development along agricultural chains, especially in terms of transparency and traceability. Blockchain technology provides traceability, security and decentralisation also for food-related data. In 2015, a web platform called Wenda tracking the integrity of perishable products along the supply chain was born in Italy. It is the only all-in-one collaborative platform to manage all your supply chain execution data in a single cloud platform. It uses the Internet of Things to check that food remains intact from delivery to large-scale distribution stores until it is purchased by the customer. The platform can support all Food & Beverage players[30] operating with perishable or sensitive products: data loggers should be autonomously (by the distributors) inserted into each food box, pallet or container to collect environmental data (geolocation, temperature, food integrity), such data are transmitted to the Wenda Information Management Hub where they are aggregated, compared and processed though proprietary algorithms. In particular, it digitizes visibility, temperature and traceability data by combining them with logistics data in the multiple stages of the products distribution. Subsequently, through advanced analytics incorporated into the Hub, product integrity can be verified in real time and from a single control point, highlighting the critical points in the distribution chain. In this way, the end-to-end visibility of the supply chain would ensure transparency, maximized product integrity and shelf-life, and increased efficiency. Producers, distributors and retailers will be able to substantially reduce losses, increase revenues and significantly reduce food waste. While assisting managing operations and decreasing returns of products with limited shelf-life from the market, the platform helps displaying the chain of responsibility.

Reuse – keeping the supply chain short

-

With a view at maintaining a short supply chain which accounts for the sole steps of cultivation, harvesting, storage, sorting, washing and packaging, fruits and vegetables producers mainly aims at the reuse of all surplus production including those products that do not meet the requirements for direct sales towards large-scale distribution.

Reuse foresees retailing at farmers markets, commercialisation through online platforms selling 'ugly but delicious' food, and donation. Despite it is often not financially profitable, benefits are high from an environmental and social point of view: fewer food losses, less wasted resources, lower waste management costs and lower-priced fruits and vegetables that fully respect nutritional quality standards.

Despite the perfect nutritional value of imperfect 'ugly' products, they are either never harvested or discarded, resulting in escalating farm-to-fork food waste problems worldwide[31]. Nowadays, multiple information channels such as governmental campaigns (e.g. the European Waste Framework Directive, the United Nations' SDGs), NGO activities (e.g. the Waste Resource Action Program in the UK), or public activities on social media (e.g. food sharing apps) provide consumers with a flood of information about sustainability issues[32]. The consequently raised consumers' awareness is taking more and more the form of conscious and green choices. Van Giesen & de Hooge[32] recently published their promising results confirming that consumers are keen to purchase suboptimal fruits and vegetables when authenticity and sustainability positioning strategies are applied. This means that sustainability truly motivates consumers to adjust their behaviour.

In Italy, fruits and vegetables gleaning or field gleaning initiatives meant for gathering food left in fields after the primary harvest or food which is not profitable is only possible upon written consent of the farm owner. Differently, it is considered a minor crime (Article 626 – Criminal Code). However, gleaning initiatives relying mostly on volunteers to harvest, pick up, sort, and deliver fresh fruits and vegetables to food banks, food pantries, churches, and families with low incomes should be boosted. Firstly, government stakeholders' actions are required. Evidence of the effectiveness of these initiatives are many such as increased consumption of healthy foods and improved dietary habits[33]. Reduced obesity rates, improved nutrition, increased food security, and reduced emissions are additional potential benefits[33].

With regards to donation, the fulfilment of this activity takes place according to what is described by the Italian law 166/2016 which regulates the transfer of food surpluses to donor subjects. The latter should take care of the food items collection or should commission it to another donor agency. The law has simplified those actions aimed at social solidarity highlighting the importance of awareness campaigns too. Key points are the establishment of an effective method for measuring food surpluses, the systematization and formalization of the surplus management process (i.e., requirements and storage), and the tracking and monitoring of the supply chain of the surplus transfer process. Incentives are provided but also obligations for supermarkets with a sales area larger than 400 m2. Donation is allowed as long as the food safety standards are respected. Instead, all those surpluses that are not considered fit for human consumption, might be sold for animal consumption once compliant with the Commission Notice (2018/C 133/02) regarding the guidelines for the feed use of food no longer intended for human consumption has been verified.

The case of an Italian start-up for fruits and vegetables surpluses reuse

-

In 2020, during the Covid-19 health emergency, an Italian start-up named Babaco Market was born to meet the needs of consumers to provide online shopping while promoting more sustainable choices. It was founded in the Lombardia region but is slowly expanding towards neighbouring regions. Their mission is finding a new market for 'ugly but good' fruits and vegetables. They operate a 100% made in Italy delivery of out of the ordinary fruits and vegetables to fight the waste problem originating from the field to the market. Their advertising campaign which poses flavour above shape, aims to be a manifesto and a value-based stance on the beauty of imperfections and on the pride of saving products that, despite their aesthetical defects, maintain their quality. This contributes raising awareness about food waste and the importance of more sustainable consumption. They collaborate with small Italian producers, often organic or SlowFood, guaranteeing them a certain economic sustainability in terms of return of collection costs plus a small income. Consumers can subscribe weekly (or every 2-weeks) for receiving one of the two types of boxes (small for 1−2 people, large for 4 people) that the start-up offers and delivers directly at home. According to seasonal availability, such boxes contain mixed fruits and vegetables and are completely plastic free.

The start-up generates very little organic waste mainly due to accidental product thermal trauma and in case of surpluses, the latter go to charities. In one year, their numbers are noteworthy: 8−9 tons of recovered product per week. Considering their small range of action (yet limited to the north of Italy), it means that this type of sustainable e-commerce supply chain supporting the agricultural sector and strengthening small productions, can be very successful especially if well-advertised. Indeed, 70% of their customers are between 25 and 45 years old, which is notably an age range very active on social networks.

Recycle – shifting towards a longer supply chain

-

When talking about organic matter recycling, sustainable waste management strategies mainly focused on energy recovery options are the first that come to mind. Anaerobic digestion, composting, landfilling, incineration and rendering are the most common ways to valorise food waste. Biomass engineering to produce green bio-plastics materials has also seen significant progress[34]. But when such organic matter is still edible, recycling strategies should aim to maintain the original destination of those food fluxes, which is on consumers' tables, guaranteeing nutritional safety.

Often fruits and vegetables surpluses that are not acceptable for the large-scale distribution as fresh products due to aesthetical imperfections enter a longer supply chain becoming feedstock in food-processing plants. Here, fruits and vegetables that are a little bruised, too ripe, under-ripe, or not meeting the expected aesthetic standard can be transformed into juices, jams, sauces, soups, dried products, puree, spirits or fruits and vegetables salads. If transformed into derivatives, surpluses do not constitute a problem in terms of food losses but they become a valuable resource. The sole processing residual waste might then be valorised as an energy source following a sustainable closed-loop approach.

Besides reducing food losses, food surpluses recycling into processed products has several other advantages: preservation of food nutritional quality, extension of shelf-life, ensured food safety, adaptation of flavour and taste, food-diversity increase, decreased price in comparison with fresh products, possibility to fortify and enrich the final derivatives and to tailor them according to specific health needs and nutritional restrictions. Indeed, food processing allows eating a greater variety of foods skipping the restrictions due to geography and seasonality. Moreover, micronutrients, like trace minerals and vitamins can be added to the final products and when such foods are produced for vegans and vegetarians they can be fortified with vitamin B12 which isn't found in plants, and soya drinks may be fortified with calcium for those who don't consume dairy products[35].

However, it is noteworthy that the tendency of the consumers is to prefer minimally processed products maintaining the original nutritional quality. Therefore, novel and mild techniques are emerging in the food processing industry panorama. Emerging technologies for maintaining the microbacterial and sensorial quality of minimally processed fruits and vegetables are as follows. Biocontrol foresees the use of natural microbiota and/or their antimicrobial products as a biopreservation technique[36]. Novel MAP strategies were mentioned previously, while novel non-thermal food processing technologies include high-pressure processing, pulsed electric field, pulsed light, irradiation, ultrasound, oscillating magnetic fields, and cold plasma technologies[37].

Digitalization, besides enabling an upgraded demand forecasting to be advised to primary producers and higher crop-production yields, appears to offer a decision support in the improvement of processing plant performances in terms of resources (water and energy) decreased consumption and waste generation reduction along raw materials processing. Raw data mined from each food processing unit shall be correctly interpreted through data analytics techniques in order to understand how the plant behaves and to build, with specific software, ideal, rigorous and dynamic simulations of real processes which will help the decisions makers in improving plant sustainability.

Certainly, deciding which type of processing might be the most sustainable from a social, economic, and environmental point of view has to be done according to each specific food surplus, season and geographical area. For example, when dealing with fruits there are pros and cons linked to different possible transformations: slicing (fresh) fruits slightly extends the shelf-life of the product, offers ease of consumption but requires a not negligible amount of frigories to maintain the product; processing fruits into juices significantly extends the shelf-life at room temperature, offers ease of consumption but juices fail to provide a sense of satiety and they are too often formulated with high quantities of sugars; dehydration offers easy-to-consume long-lasting products at room temperature but with the drawback of delivering a significant amount of calories[38]. Other challenges are posed by market trends and consumer preferences. Besides, such fruits and vegetables surpluses are not standardised either in terms of typology or in terms of quality. Therefore, a processing equipment deed to process the sole surpluses should be flexible enough to treat small and large amounts of raw materials and at different degrees of maturation. It ought to be clear that designing a process capable to deliver a service with such a high degree of uncertainty is not an easy task. In such context and in relation to a specific reality under study, risk engineering can play an important role allowing accounting for hazards and threats associated with the identified opportunities. When evaluating complex systems such as food processes, a simulation-based approach is necessary to explore the uncertainties and clarify what might be the impact of different solutions[38]. Such output information will be of paramount importance for decision makers both in case of having to choose to which processing plant sending their food surpluses and in case of purchasing the most convenient equipment for their surpluses.

Another mechanism to recycle surplus food and, therefore, to reduce losses and waste is to use it as animal feed. Indeed, any material that is processed for use in animal feed does not fall within the legal definition of waste. In this case, fruits and vegetables surpluses, that for logistic issues or for the insufficient remaining product life can not reach their intended destination which is human consumption, become suitable ingredients in animal feeds. On top of that, food surpluses valorisation can be accomplished through their integration in edible-insects biorefineries[39]. In particular, insect-based bioconversion of fruits and vegetables surpluses would turn into an opportunity for producing marketable proteins, while simultaneously fulfilling nutrients circularity[39].

Despite being borderline between loss avoidance and waste upcycling, with a reference to the last mentioned concept of nutrients circularity, the extraction of bioactives, besides dietary fibres and proteins, is worth mentioning. Along with solvent extraction, there is a number of novel extraction techniques (i.a. supercritical fluid extraction or micro-wave / US / enzyme assisted extractions)[40]. However, one of the main limitations in the use of these recovered bioactives is their sensitivity. Therefore, to cope with fast degradation phenomena, encapsulation is strictly required[41].

The case of Italian pear surpluses recycling

-

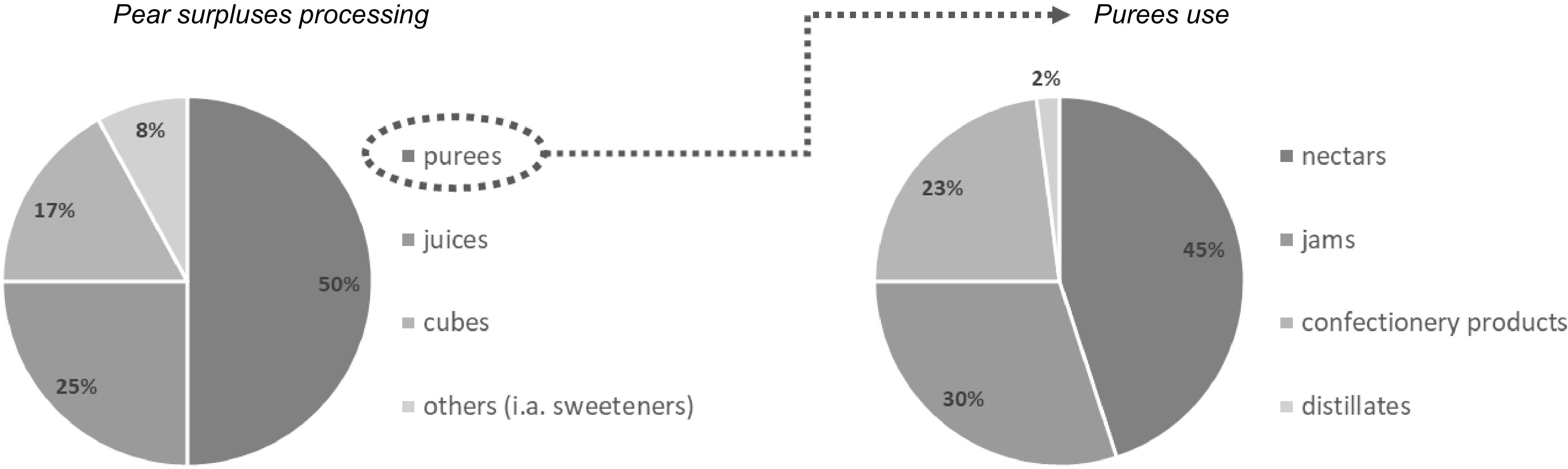

Italy is among the largest producers of pears in the European Union. In particular, Emilia-Romagna is the main Italian region dedicated to this cultivation. In 2020, the Emilia-Romagna pear protection consortium recorded a total production of 610 thousand tons. An interview with 10 Italian companies involved in the production of pears reveals that about the 15% of the entire production is made up of pears that cannot be sold for fresh consumption. Therefore, about 91 thousand tons of pears constitute food surpluses mainly due to damages during harvesting or transport, to insects and pathogens. Such pear surpluses, are sent to various food processing companies for their transformation into derivatives (Fig. 2) such as juices and semi-finished products like purees and cubes (the latter being used as candied fruits or in yoghurt with fruits pieces). Purees, on the other hand, can be used to obtain nectars, jams, pear-based distillates and pulps for filling confectionery products.

Innovative ideas that might be embraced at a national level are listed in Table 2.

Table 2. Innovative technologies that can be applied on the 3Rs – Reduce, Reuse, Recycle – level.

Innovation technologies Reduce Invisible, edible coating made from wasted agricultural products to extend the shelf life of fruits and vegetables (up to five times)[42]. Perfect for developing countries where the difficulties involved in getting harvested products to market before they spoil is the major cause of food waste. Active packaging containing sachets for the release of 1-methylcyclopropene (1-MCP), a plant hormone which sends a signal to fruits that it is not yet time to ripen[43]. Suitable for climacteric fruits. Solar-powered cold storage[44] can help reduce costs for low-income producers. Plant extracts (e.g. phenolic compounds) and essential oils (i.a. eucalyptus, hinoki, nutmeg, cinnamon, oregano) to control post-harvest diseases[45]. Reuse Online platforms (i.a., FoodCloud[46] is an inspiring technology platform born in Ireland), and the IoT can help to optimally manage the timing and logistics for food-sharing, and intelligent redistribution. New business offering - 'trash-to-table' concepts[47]. Upcycling and redistribution business is booming. Indeed, it is growing the number of food companies and start-ups committed to 'circular' sustainable practices. Recycle Valorisation of food and beverage remains into luminescent carbon dots and their subsequent transformation into light-emitting diodes[47,48]. LEDs transform electricity to light by using quantum dots with luminescent properties[48]. Innovative technologies used to value waste and by-products (e.g. recovery of bioactive compounds with antioxidant capacity, which can be natural substitutes for traditional synthetic additives or energy-recovery intensification) from the agri-food industry. Among others laser ablation, electrotechnologies (pulsed electric fields, high voltage electrical discharges, non-pulsed electric fields - ohmic heating and moderate electric field), radiofrequency drying, ultrasound-assisted extraction (UAE), high hydrostatic pressure (HHP) and pressurized fluids (sub and supercritical fluid extraction), nanotechnology can be mentioned[49]. Use of natural fibres from vegetables and fruit surpluses for the production of bio-textiles[50]. -

The issue of fruits and vegetables surpluses encompasses negative social, economic, and environmental implications. The possibilities to save these edible food volumes are many. Agriculture 4.0 has a new potential for meeting the quality standards requirements of large chains, improving harvesting yields and better forecasting climatic adverse events. Indeed, sustainability is achieved through a coordinated management of the process and digitalization has the potential for the optimization of the operations. For engaging such a tool, a complete and systematic data collection of the value chain is necessary. Actually, without measurements, it will not be possible to make thoughtful decisions but only to jump to conclusions.

Of paramount importance is strengthening the exchange of precise information between the stakeholders of the entire food supply chain, to have a better forecast of the offer, of the demand, and of the consumers' preferences. Education campaigns aimed at raising the awareness about the sustainability and safety anent the consumption of food items not meeting the aesthetical standards for large distribution retail, have the strong potential of guiding consumers' choices. Surpluses donations and recycling into processed food are well-grounded realities. However, improving logistics and shortening the decision making time for deciding how to manage fruits and vegetables surpluses still have room for improvement in an effort to cope with the short shelf-life of such fast ripening items.

Policy should be linked, within a comprehensive and integrated approach to technology, incentives, infrastructure, information and behavioural science to bridge the gap between research, real-life and governance and to make all systems mutually supportive and complementary to each other. Conclusively, dissemination is a requisite for the spread of pioneering ideas and practices since food service managers are still mostly unaware of radical innovations.

This research was funded by the Lombardy Regional Government: project ESPERA - Economia circolare e sostenibilità della filiera della pera IGP del Mantovano (Circular economy and sustainability of the production of PGI Mantua pears).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Girotto F, Piazza L. 2023. The 3Rs applied to fruits and vegetables surpluses: virtuous examples from Italy. Food Materials Research 3:25 doi: 10.48130/FMR-2023-0025

The 3Rs applied to fruits and vegetables surpluses: virtuous examples from Italy

- Received: 06 June 2023

- Accepted: 23 July 2023

- Published online: 11 October 2023

Abstract: When facing environmental issues associated with food waste, it is necessary to look upstream at the root causes. At the very beginning of the supply chain, there is the first cause of waste generation: unrecovered agriculture surpluses. Given the richness and diversity of farmlands, Europe is a big market for fresh fruits and vegetables, where Italy and Spain are the leading producers. In Italy, the fruits and vegetables sector represents a business of 13 billion Euros and it continues growing. Fruits and vegetables are highly perishable and their marketability as fresh products is severely limited by high quality standards. Fruits and vegetables surpluses are due to several variables like heterogeneous market demand, weather, pests, labour availability, crop gluts, production error and strict standards. Reduction strategies must be given absolute priority targeting digital agriculture techniques (agriculture 4.0), improved forecasting and detailed information exchange among all supply chain stakeholders. Such strategies must then be followed by reduction and recycling ones. In particular, the latest actions shall be focused on avoiding losses and waste generation through fruits and vegetables surpluses valorisation preferably keeping them within the food supply chain mainly through donation and processing, preferably based on green innovative technologies. This review aims to appraise existing accomplishments of fruits and vegetables surpluses minimization gleaned from 3Rs initiatives and to point out virtuous examples within the Italian fruits and vegetables production panorama.

-

Key words:

- 3Rs /

- Food surpluses /

- Circular economy