-

A scientific field known as 'food safety' studies how to handle, prepare, and store food to minimize the risk of food-borne illnesses and protect customers. Furthermore, food safety is a global issue that is causing both the food production and consumer sectors to become increasingly concerned. Food safety procedures aid in maintaining the wholesomeness and quality of food along the food production chain, which promotes health. The use of optical sensors, which can assess food health using practical and affordable methods, can help deal with such a predicament. Within the purview of food safety, to satisfy rising demand and increase profits, milk, an essential food item consumed worldwide, is frequently adulterated. The most common adulterants include starch, urea, water, and dangerous compounds like melamine, which are extremely dangerous to health[1,2].

The Food and Agriculture Organization (FAO) states that milk is an important source of vitamins, minerals, and proteins that are needed by people all over the world. However, according to estimates from the World Health Organization (WHO) and the Food and Agriculture Organization (FAO), approximately 10% of the world's milk supply is tainted in some form, raising serious health hazards for consumers, particularly in areas where strict enforcement of food safety laws is lacking. There have been numerous reports of milk adulteration with water, urea, starch, and dangerous chemicals like melamine, which can cause major health problems like kidney damage, gastrointestinal disorders, and in extreme situations, death[3,4].

Almost 200 million people worldwide suffer from foodborne illnesses each year, according to the WHO, with milk and dairy products being the main culprit because of their vulnerability to adulteration and contamination. Melamine poisoning in baby formula in China in 2008 was one of the most prominent cases of milk adulteration, impacting over 300,000 newborns and resulting in six recorded deaths. Such occurrences demonstrate the need for quick, accurate, and affordable ways to identify adulteration to protect the public's health[5].

Additional data highlights the importance of milk in underdeveloped nations, where milk fraud is more common. A recent assessment conducted by the Food and Drug Administration of India, for instance, revealed that up to 68% of milk samples gathered from different states did not adhere to the recommended safety requirements. Synthetic milk ingredients, formalin and detergents are common adulterants; many of these substances have been connected to serious health problems[6,7].

Traditional detection techniques, such as spectroscopy, and chromatography, are trustworthy but time-consuming, expensive, and need trained personnel[1−3]. As a result, the demand for quick, affordable, and trustworthy sensing technologies for the real-time detection of adulterated milk is rising. The term 'milk adulteration' describes the deliberate or inadvertent addition of foreign materials to milk, which can lower the milk's quality, safety, and nutritional value. Water, urea, formaldehyde, detergents, and antibiotics are examples of common adulterants. These ingredients can be added to milk for several purposes, including boosting profit margins, hiding spoilage, or enhancing the overall appearance.

Given these alarming statistics, there is a pressing need for rapid, sensitive, and affordable detection technologies that can be deployed on-site for routine quality checks. Traditional detection methods, while accurate, often require sophisticated equipment and trained personnel, which limits their accessibility in low-resource settings. So far as quick and reliable sensing schemes are concerned, the sensitivity, resilience, and real-time functionality of fiber optic sensors have made them a viable option. The U-shaped fiber optic sensor, we propose, aims to address these limitations by providing a simple, sensitive, and portable solution that can be used in a variety of settings, from dairy farms and distribution centers to consumer-level testing. The improved interaction between the guided light and the surrounding medium makes the U-shaped fiber optic sensor stand out among the other designs of fiber optic sensors. With an emphasis on their design, sensing mechanisms, experimental testing, and possible applications, this research investigates the viability of U-shaped fiber optic sensors for the detection of milk adulteration[7−19].

-

The adopted traditional methods for detecting milk adulteration typically involve lab environments with trained personal. Some of them are described in the following sections.

Chemical analysis

-

This involves using chemical reagents to test the presence of specific adulterants. As it is solely chemical reagents based, it is not environment friendly.

Physical analysis

-

This includes measuring properties like density, viscosity, and freezing point. As milk is a complex matrix, it is composed of several constituents. Now, pure milk has different physical attributes such as density and viscosity in ambient conditions. When it is adulterated, there occurs variation in these physical parameters. The altered variations lead to qualitative analysis of the extent of adulteration[9,10].

Microscopic examination

-

This involves examining milk samples under a microscope to identify foreign particles or microorganisms. Here also, pure milk as well as adulterated milk samples exhibit differently under a microscope. Accordingly, the adulterants can be qualitatively detected when those samples are inspected under a microscope[11−13].

Spectroscopic analysis

-

This uses techniques like infrared spectroscopy and near-infrared spectroscopy to analyze the molecular composition of milk. For instance, the UV-vis spectra can be cited. Depending on the concentration of foreign substances present in samples, there arises either a peak shift or a decline in absorbance magnitudes. These criteria directly hint at the extent of adulteration induced in milk[14,15].

Although these techniques work well, they frequently call for specialized tools, skilled labor, and a large amount of time. Rapid on-site testing may become difficult as a result, especially in isolated or resource-constrained locations.

-

For a wide range of uses, including food quality evaluation, biomedical diagnostics, and environmental monitoring, fiber optic sensors have been extensively researched. They are based on the idea that light travels through optical fibers and is affected by changes in its surroundings, such as alterations in its refractive index. The sensor can identify impurities or other variations in the sample by examining these changes. Numerous sensing approaches, such as electrochemical sensors, spectroscopic techniques, and biosensors, have been investigated for detecting milk adulteration. These techniques, however, frequently call for intricate setups or are inappropriate for on-site testing. Conversely, fiber optic sensors—especially U-shaped ones—offer a more straightforward and reliable method.

U-shaped fibers belongs to a special configuration of optical fibers. As far as the configurations are concerned, there are three configurations such as D-shaped, U-shaped, and tapered. Among these, tapered and D-shaped fibers are difficult to fabricate because of the intricate design issues. D-shaped fibers provide a larger interaction area with impinging light which is again crippled by loss. Likewise, the tapered fiber suffers from a low waist angle. In such circumstances, U-shaped fibers promise easier handling and it offers efficient light interaction in the bending tip—thereby minimizing loss. Because of the efficient interaction between light and the sample generated by the U-shaped fiber's bending curvature, it enables a robust response of modulated light intensity while being more sensitive to changes in the refractive index brought on by adulterants[16−21].

U-shaped fiber optic sensors have been shown in earlier research to be capable of detecting a wide range of liquid pollutants. They have been used, for instance, to find heavy metals, ethanol, and glucose in water. Because of their versatility in measuring refractive indices, they are particularly useful for identifying adulterants in milk, where even minute compositional variations can have a substantial impact on refractive index[17−19].

-

The basis of U-shaped fiber optic sensors is evanescent wave sensing. An evanescent field is produced when light passes through an optical fiber and a tiny amount of the light penetrates beyond the fiber's surface. The surrounding medium, in this case milk, interacts with this field, and variations in the media's refractive index impact the transmitted light's phase and intensity.

Because the U-shaped fiber exposes more surface area to the sample, it greatly improves this interaction. More of the evanescent field can interact with the surrounding medium when the fiber is bent into a U shape because this changes the light path inside the fiber.

This enhanced interaction makes the U-shaped fiber optic sensor more sensitive to small changes in the refractive index compared to straight fiber sensors[15−17].

So far as the detection of milk adulteration is concerned, pure milk possesses a constant refractive index. Due to the presence of adulterants such as detergents, urea, or melamine, the refractive index is altered, and these variations can be detectable via the U-shaped fiber optic sensor. The sensor's output is typically analyzed using an optical spectrum analyzer or a photodetector, which measures changes in light intensity and wavelength. To further substantiate the capability of U-shaped fibers, a comparative Supplementary Table S1 has been included as supplementary information.

-

Several key issues are to be checked to make a robust U-shaped fiber optic sensor which directly impacts sensitivity as well as accuracy. First is the choice of fiber material. Primarily, it includes silica due to its high transparency and low attenuation. However, for enhanced sensitivity, fibers with higher refractive indices, such as doped silica or polymer fibers, may be used. Secondly, the bending radius plays a vital role. The curvature of the U-shape is critical in determining the sensor's sensitivity. A smaller bending radius increases the evanescent field's interaction with the surrounding medium, but too small a radius can cause excessive light loss, reducing the sensor's effectiveness. An optimal bending radius must be chosen to balance sensitivity and signal strength.

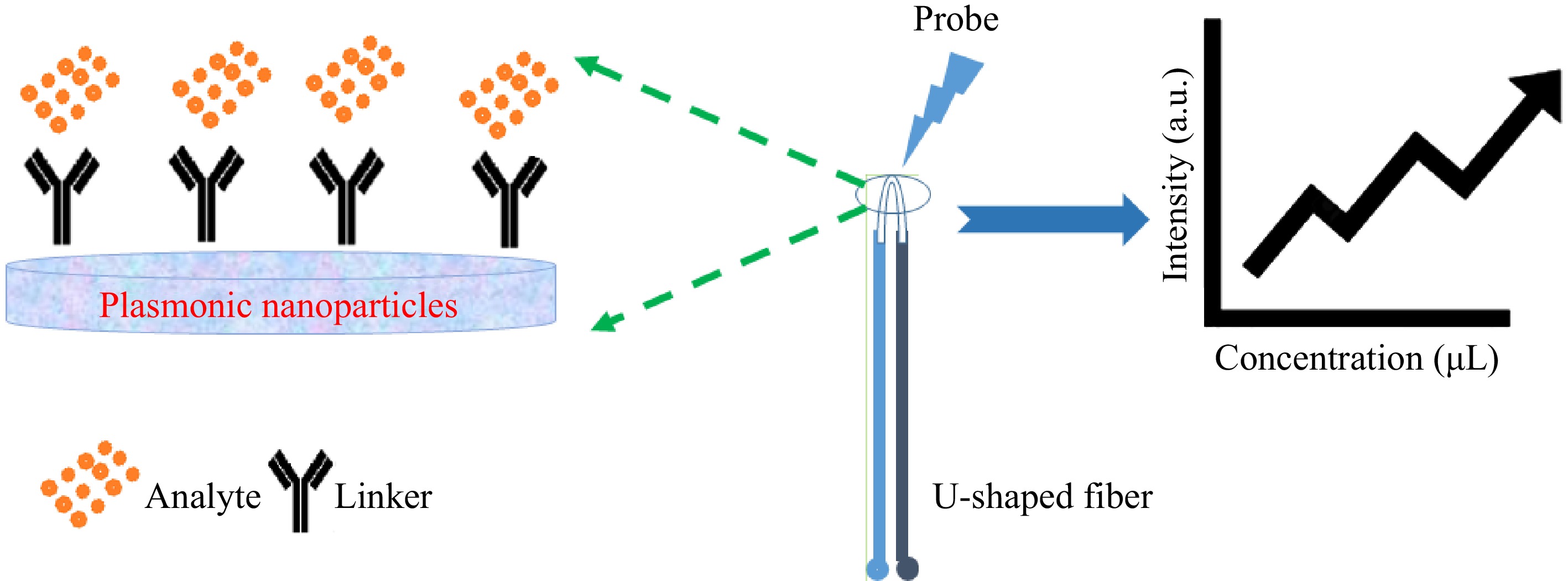

To cater to specific analytes, the U-shaped fiber's surface can be coated with functional materials to enhance its interaction with specific adulterants. When the adulterant-specific functional material is conjugated with plasmonic nanoparticle coating, the localized surface plasmon resonance (LSPR) effect can be exploited which amplifies the sensor's response to changes in the refractive index. Apart from this, a suitable optical source and detector are required. The light source for the U-shaped fiber optic sensor is typically a laser diode or LED, emitting light in the visible or near-infrared range. The detector is chosen based on the light's wavelength and the expected changes in intensity due to adulteration. Last but not least, a flow cell or static chamber can be used to hold the milk sample. The design should allow for continuous flow in real-time applications or static testing for laboratory settings.

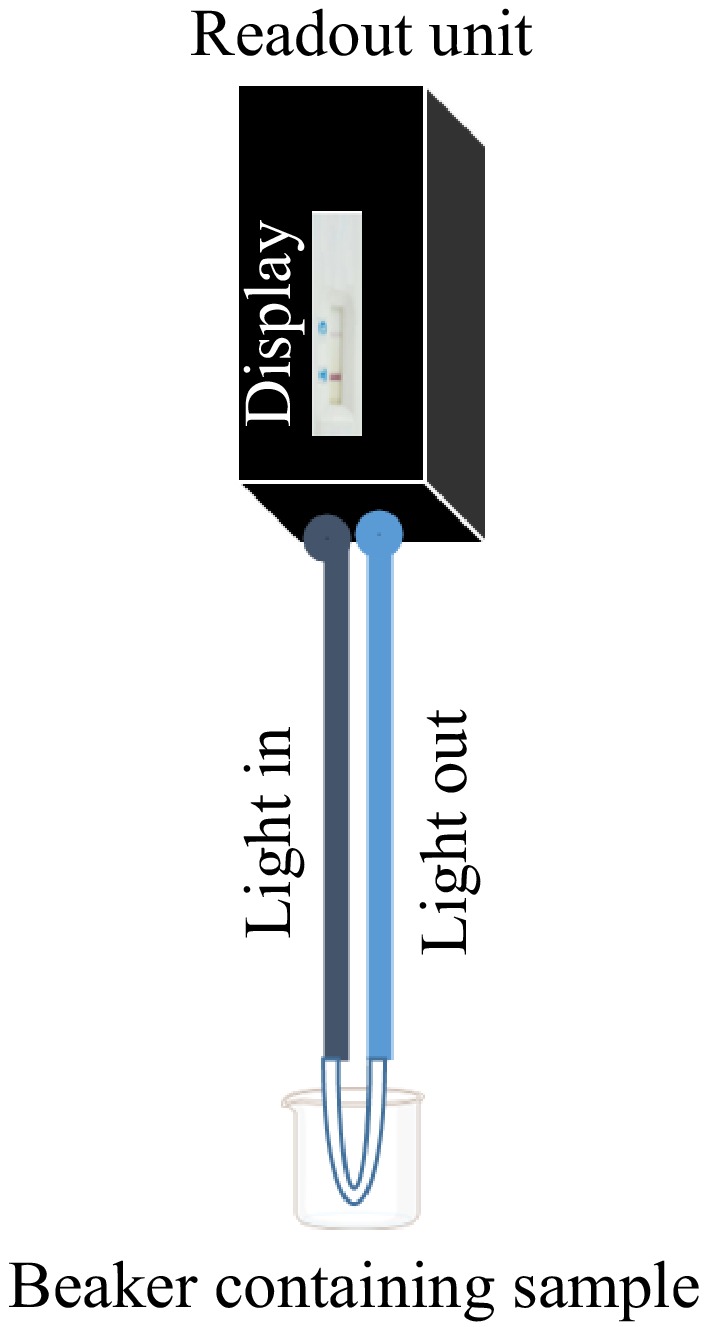

The schematic of the feasible fiber optic setup is shown in Fig. 1. As can be seen, the fiber cable has been bent into a U-shape which is finally dipped into the sample holder. Here, the beaker contains the adulterated milk. As is evident, the incoming light interacts with adulterated milk via the functionalized probe.

When the milk sample is introduced into the U-shaped region of the fiber, the light propagating through the fiber interacts with the sample, causing a shift in the phase of the light. This phase shift/change in intensity can be measured and correlated to the refractive index of the milk sample.

Different adulterants can have different effects on the refractive index of milk. For example, water has a lower refractive index than milk, while urea and formaldehyde can increase the refractive index. By monitoring changes in the phase shift/altered intensity of the light propagating through the U-shaped fiber, it is possible to detect the presence of adulterants in milk.

To evaluate the feasibility of the U-shaped fiber optic sensor for milk adulteration detection, a series of experiments can be conducted using different adulterants in varying concentrations. The following steps outline the experimental process:

1. Sensor fabrication: A silica fiber was bent into a U-shape with a radius of 10 mm. The fiber was coated with gold nanoparticles to enhance the LSPR effect.

2. Sample preparation: Pure milk samples were obtained, and adulterants (detergent, urea, and melamine) can be added in concentrations ranging from 0.1% to 10% by volume. These concentrations are chosen to represent common adulteration levels found in real-world scenarios.

3. Optical setup: A laser diode (λ= 650 nm) can be used as the optical source. The light is being coupled into the U-shaped fiber. The transmitted intensity can be effectively measured by a suitable photodetector.

4. Data collection: On immersing the probe in the milk sample, the transmitted light intensity is recorded. Alterations in intensity are then correlated with the concentration of adulterants.

5. Data analysis: The sensor's response can be analyzed by plotting the changes in light intensity against the adulterant concentration.

-

Figure 2 illustrates the sensing mechanism. The analyte-specific functional coating in conjugation with plasmonic nanoparticles in the probe region is the main agenda here. It is also possible to use linkers such as aptamers to enhance the sensitivity. For a pure sample, the transmitted intensity will be the same for all concentrations. However, when the probe is dipped in adulterated samples containing melamine, urea etc., the transmitted intensity may show a decline or rise depending on the specific interactions with the probe. Apart from this, the increasing concentration of one type of adulterant may lead to one specific intensity profile which is subject to varying degrees of LSPR. Overall, the results of the experiments have the potential to demonstrate the high sensitivity of the U-shaped fiber optic sensor for detecting milk adulteration. The sensor could detect changes in the refractive index caused by even small concentrations of adulterants[18−21].

Figure 2.

Schematic of the U-shaped sensing probe with linker and analyte along with corresponding output.

As far as the sensitivity of the sensors is concerned, it is assessed via the following formula:

Sensitivity, S= |ΔI/Ic|.

Here, Δ I = IA − IC, where IA and IC refers to the intensity values corresponding to the adulterated and control samples respectively. Owing to better functionalization and least interference, it is feasible to achieve higher sensitivity values of ~0.001. Likewise, the limit of detection (LOD) of this kind of fiber optic set-up has been established to reach below ppm. At the same time, they also yield a detection range of a few μL to mL[22−25].

-

The U-shaped fiber optic sensor presents a promising solution for milk adulteration detection, with potential applications in:

1. Dairy industry: The sensor can be integrated into automated systems for continuous monitoring of milk quality during processing and distribution. Its real-time detection capabilities can help ensure compliance with food safety standards.

2. Consumer-level devices: The sensor's compact design and low cost make it suitable for portable devices that consumers can use at home to check the purity of milk.

3. Regulatory bodies: Food safety authorities can use the sensor for on-site testing of milk samples in markets and distribution centers, providing a rapid and reliable method for identifying adulteration.

While U-shaped fiber optic sensors offer a promising approach for milk adulteration detection, there are some challenges to be addressed as follows:

Interference: The sensor may be susceptible to interference from other factors, such as temperature variations or mechanical vibrations.

Calibration: Accurate calibration of the sensor is essential for reliable measurements.

Cost: The cost of fiber optic sensors and associated equipment may be a limiting factor in some applications.

Future research may focus on developing more robust and cost-effective U-shaped fiber optic sensors for milk adulteration detection. Additionally, exploring the integration of these sensors with other technologies, such as microfluidics or wireless communication, could enhance their capabilities and applicability. There is further scope for optimizing the sensor's design, particularly in terms of improving selectivity and sensitivity for a broader range of adulterants. Additionally, the development of a multi-channel sensor capable of detecting multiple adulterants simultaneously is an area of ongoing research.

-

In essence, this paper demonstrates the feasibility of using U-shaped fiber optic sensors as a practical solution for detecting milk adulteration. The sensor's high sensitivity, rapid response time, and potential for real-time monitoring make it a valuable tool for the dairy industry, regulatory bodies, and consumers. With further optimization and validation, this technology could play a crucial role in improving food safety and ensuring. By leveraging the unique properties of these sensors, it is possible to develop systems that can be used for on-site monitoring of milk quality and ensuring consumer safety. As technology continues to advance, we can expect to see even more innovative applications of fiber optic sensors in the food industry.

-

The author confirms sole responsibility for the following: study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

-

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

-

The author declares that there is no conflict of interest.

- Supplementary Table S1 It provides a comparative analysis of the U-shaped fiber optic sensor with other popular rapid detection methods for milk adulteration.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Biswas R. 2024. U-shaped fiber optic sensor as a feasible solution for assessing adulteration in milk. Food Materials Research 4: e037 doi: 10.48130/fmr-0024-0028

U-shaped fiber optic sensor as a feasible solution for assessing adulteration in milk

- Received: 01 October 2024

- Revised: 08 November 2024

- Accepted: 20 November 2024

- Published online: 31 December 2024

Abstract: Milk adulteration is a pervasive global issue, particularly in developing nations. In order to meet consumer demand, various adulterants such as water, urea, and melamine are often added to increase the quantity or alter the properties of milk. These foreign substances lead to unwanted ailments if taken above a permissible level. The traditional approaches for detecting and analyzing adulterants often require sophisticated labs along with trained personnel. To address these impending issues, it is imperative that there should be a cost-effective rapid analytical scheme. Given these facts, this paper explores the feasibility of using U-shaped fiber optic sensors as an efficient and sensitive approach to detect milk adulteration. By leveraging the light propagation characteristics of fiber optics and the Localized Surface Plasmon Resonance (LSPR) phenomenon, this sensor can detect minor changes in the refractive index of milk caused by adulterants. Accordingly, this work delves into the working principle of U-shaped fiber optic sensors, design considerations, and the potential for scalable applications in milk quality assurance.